News

Site Editor

Site

/uploads/image/658e1b5398ef3.png

Heat sinks are essential components for managing thermal energy in electronics. Whether you're designing your own cooling system or selecting a heat sink for your device, understanding the basics of heat sink design is crucial to ensure optimal performance.

Site

/uploads/image/658e1b5398ef3.png

Heat sinks are essential components for managing thermal energy in electronics. Whether you're designing your own cooling system or selecting a heat sink for your device, understanding the basics of heat sink design is crucial to ensure optimal performance.

Heat Sink Design Guide: Understanding the Basics and Best Practices

Views: 231

Author: Site Editor

Publish Time: 2025-02-21

Origin: Site

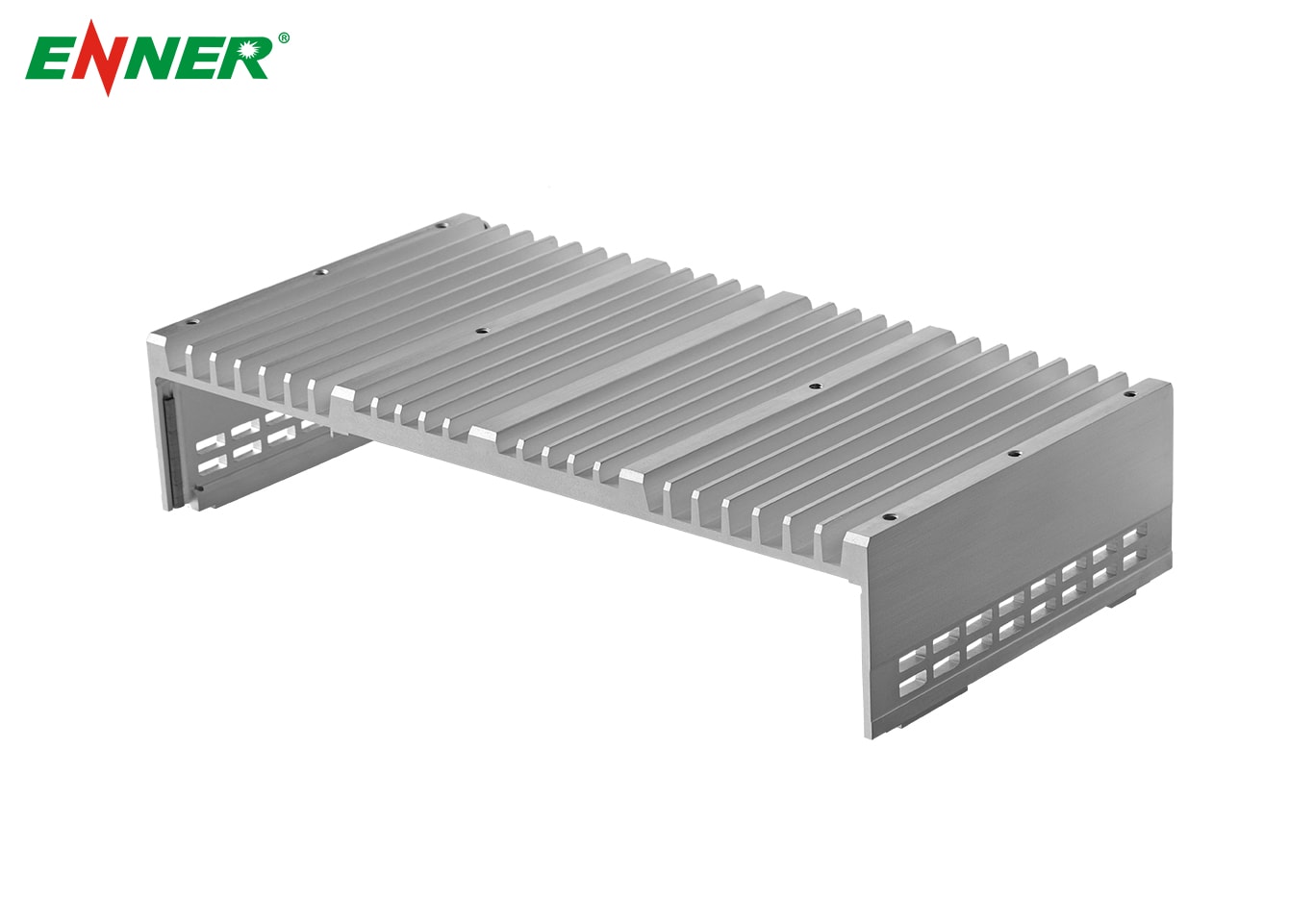

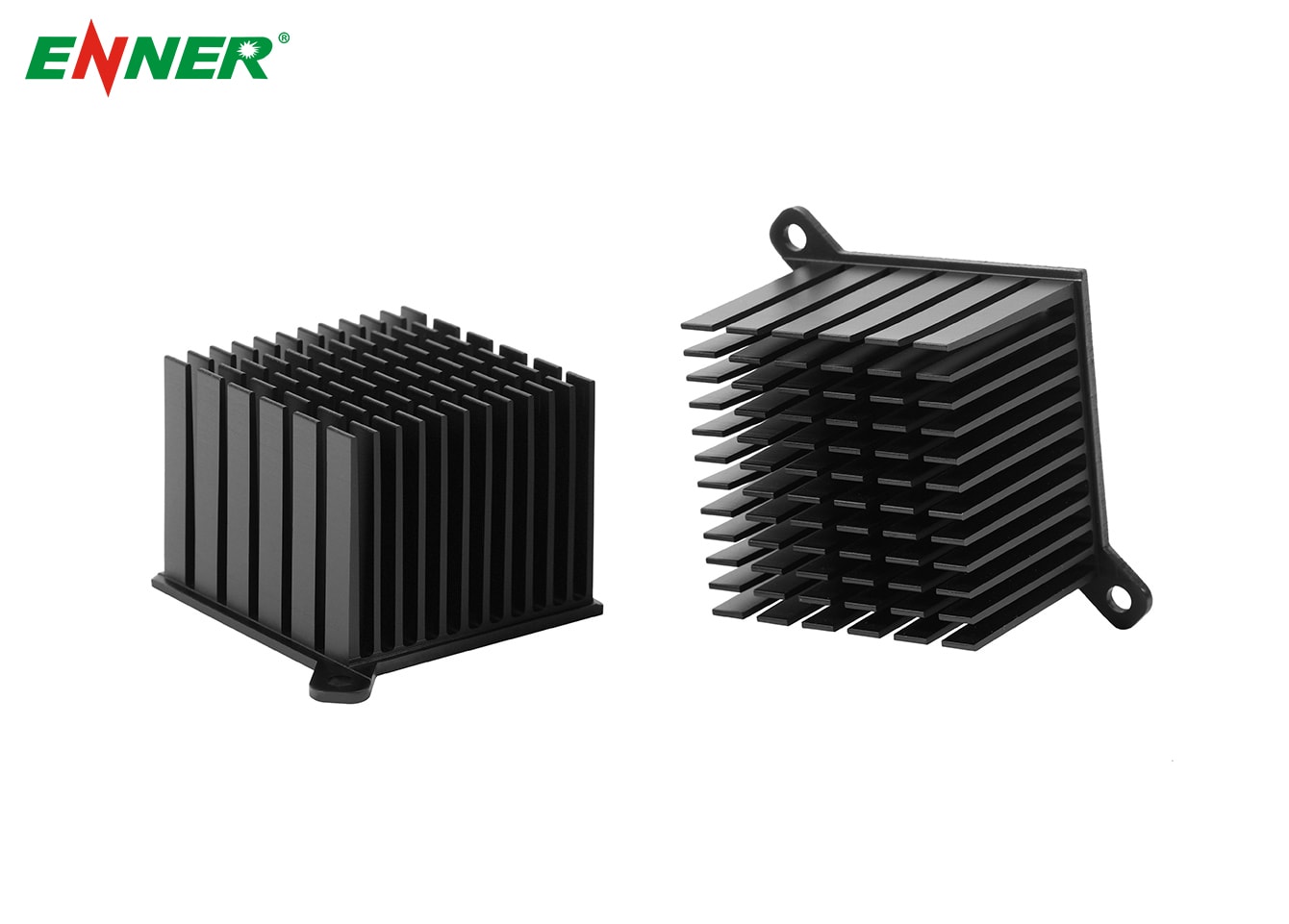

Heat sinks are essential components for managing thermal energy in electronics. Whether you're designing your own cooling system or selecting a heat sink for your device, understanding the basics of heat sink design is crucial to ensure optimal performance.

What is a Heat Sink?

A heat sink is a device used to dissipate heat generated by electronic components, usually via natural or forced convection. In simpler terms, it's a way of drawing heat away from your electronics to keep them cool and functioning efficiently.

Natural Convection Heat Sink Design

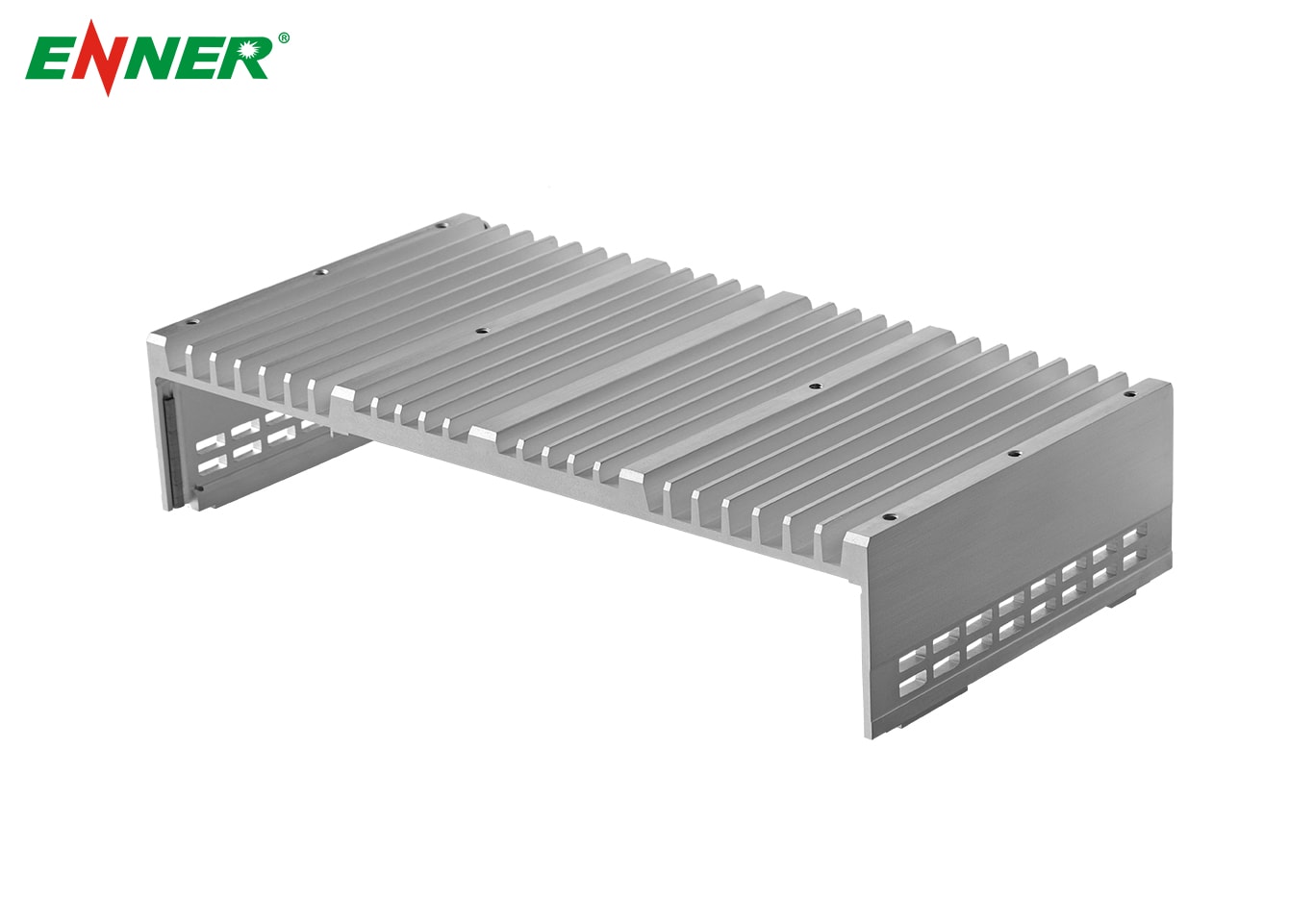

Envelope Size and Base Thickness

When designing a heat sink for natural convection, it's essential to start with the envelope volume. The base thickness should be thicker at the heat source and gradually thinner towards the edges. This helps distribute heat efficiently across the heat sink, allowing for optimal cooling. The base thickness must be calculated based on the heat input power.

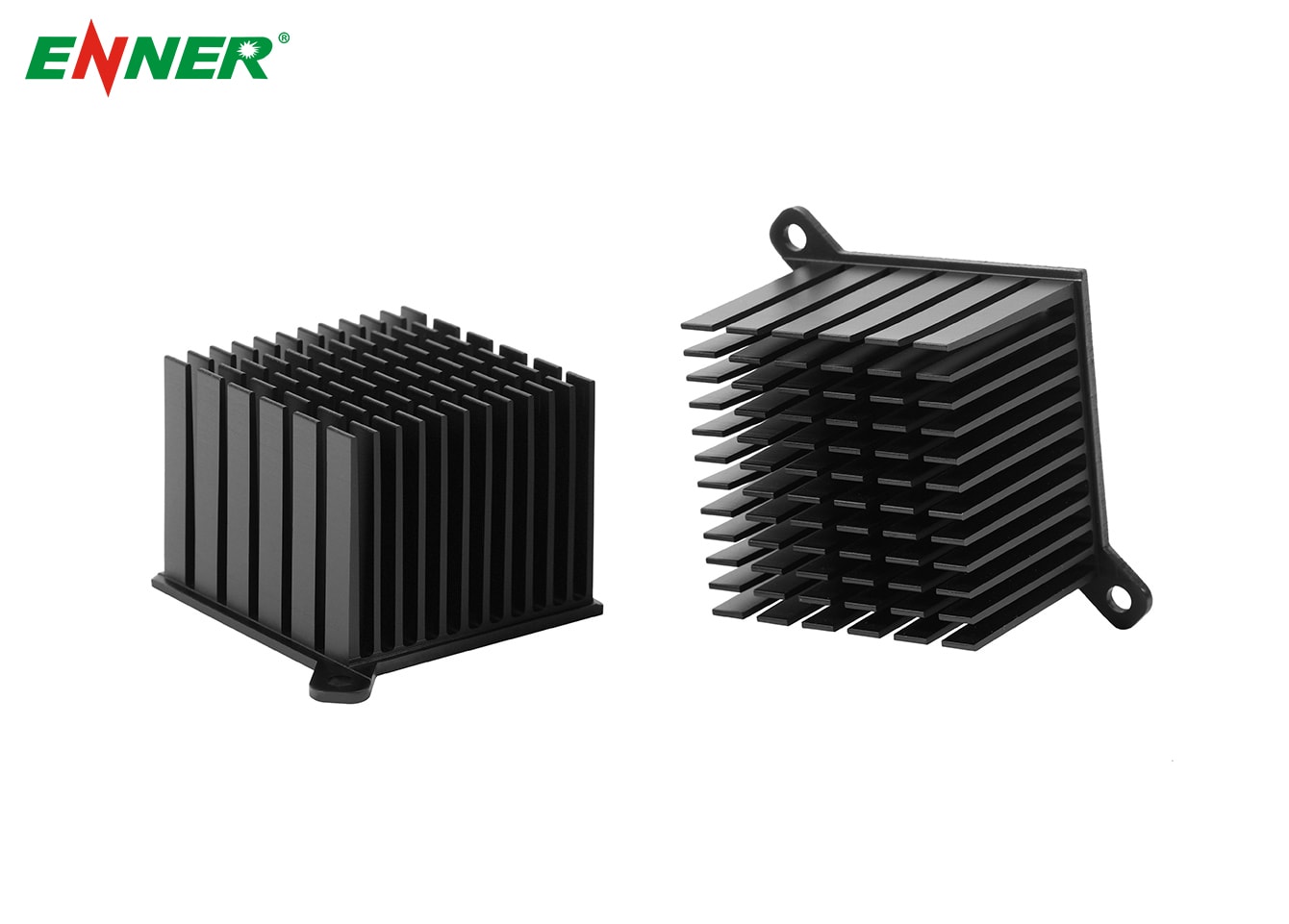

Fin Design

Fins are an integral part of heat sink design. The thickness and spacing of the fins play a significant role in heat dissipation. Ideally, the fin spacing should be at least 4mm to allow natural convection to flow smoothly. Finer fin spacing will reduce the heat sink's surface area, negatively affecting the cooling performance.

-

Fin Angle and Shape: Most heat sinks have fins with an angle of about 3 degrees, optimizing air flow.

-

Fin Thickness and Height: Thin fins can create heat transfer issues, while thicker or taller fins may reduce surface area. Striking the right balance is key.

Surface Treatment

Surface treatment, such as anodizing or alumite processing, enhances a heat sink’s radiative performance, improving heat dissipation. While the color of the surface doesn't matter as much, rough surfaces are generally preferred in natural convection designs.

Forced Convection Heat Sink Design

In systems where fans or forced air flow are used, the goal is to maximize heat transfer efficiency by increasing air speed and surface area.

Increasing Air Flow Speed

The simplest way to improve forced convection is to increase airflow. Higher fan speeds or more powerful blowers help move air quickly across the fins, improving heat dissipation.

Fin Design for Forced Convection

-

Flat Fins: Cutting the fins into shorter segments increases the heat conduction coefficient. This is particularly effective when airflow direction is unpredictable, such as in motorcycle engines.

-

Pin Fins: Pin-shaped fins are lighter, smaller, and more efficient for forced convection cooling. They have better directional heat transfer properties and offer higher volumetric efficiency.

Radiating Fins and Flow Direction

For designs where the fan blows air upwards, consider radiating fins. These designs help direct airflow in the most efficient manner and reduce wasted air movement.

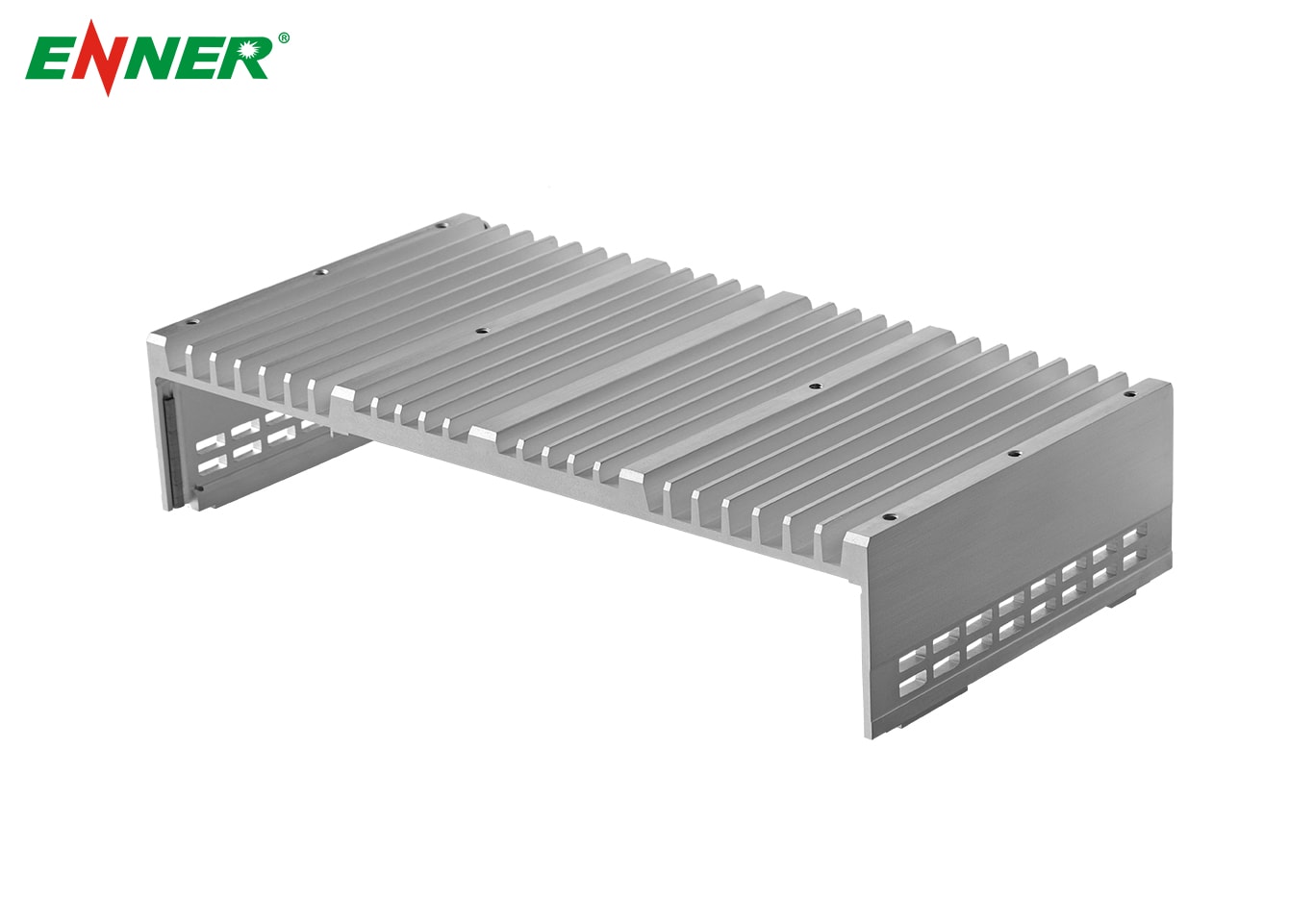

Industry Guidelines for Heat Sink Design

When designing or selecting a heat sink, there are several industry guidelines to follow:

-

Larger Surface Area Improves Heat Dissipation: The bigger the heat sink's surface area, the better the heat dissipation.

-

Optimized Airflow: Positioning the heat sink in a way that allows optimal airflow will maximize cooling efficiency.

-

Material Choice: Copper and aluminum are the most effective materials due to their high thermal conductivity.

-

Thickness vs. Length: It is more effective to increase the thickness of the heat sink than to make it longer.

-

Surface Treatment for Durability: Anodized surfaces are more resistant to corrosion and improve heat dissipation.

-

Cost Efficiency: Always consider the practicalities of manufacturing and material costs.

Choosing the Right Heat Sink for Your Application

When selecting a heat sink, consider the following:

-

Current Load and Required Heat Dissipation: Make sure the heat sink's design matches the amount of heat your device will produce.

-

Operating Environment: Whether you're working in a natural convection, forced air, or water-cooled environment will determine the type of heat sink required.

-

Form Factor and Space Constraints: The size of your device will influence the heat sink shape and size.

Conclusion: Keep Your Devices Cool and Efficient

Proper heat sink design is crucial to maintaining the performance and longevity of electronic devices. Whether you're designing a custom cooling system or selecting an off-the-shelf heat sink, keeping these principles in mind will help you achieve the best results. At Enner , we are at the forefront of these advancements, committed to delivering state-of-the-art heat dissipation solutions.