In our pursuit of exceptional cooling solutions, our company always prioritizes innovation and performance. Focusing on the superior properties of aluminum, we have launched a series of cooling products, including heat pipe cooling systems, CNC machined parts , heat spreaders, extruded heat sinks, turned heat sinks, zip-fin heat sinks, stamped heat sinks, and related accessories. These products are designed based on a deep understanding of aluminum's excellent thermal conductivity and the application of precise craftsmanship, reflecting our commitment to product quality and meeting customer needs.

Aluminum Heat Pipe Cooling Solutions

Our aluminum

heat pipe cooling technology

utilizes aluminum's high thermal conductivity to achieve efficient heat dissipation, suitable for high-performance equipment requiring rapid heat transfer. These solutions are designed to provide exceptional thermal management performance for applications such as electronic devices and computer systems.

Aluminum CNC Machined Parts

Taking advantage of aluminum's machinability, we offer custom

CNC machined parts

to meet various precision cooling needs. These parts combine aluminum's lightweight and high thermal conductivity, suitable for demanding custom cooling solutions.

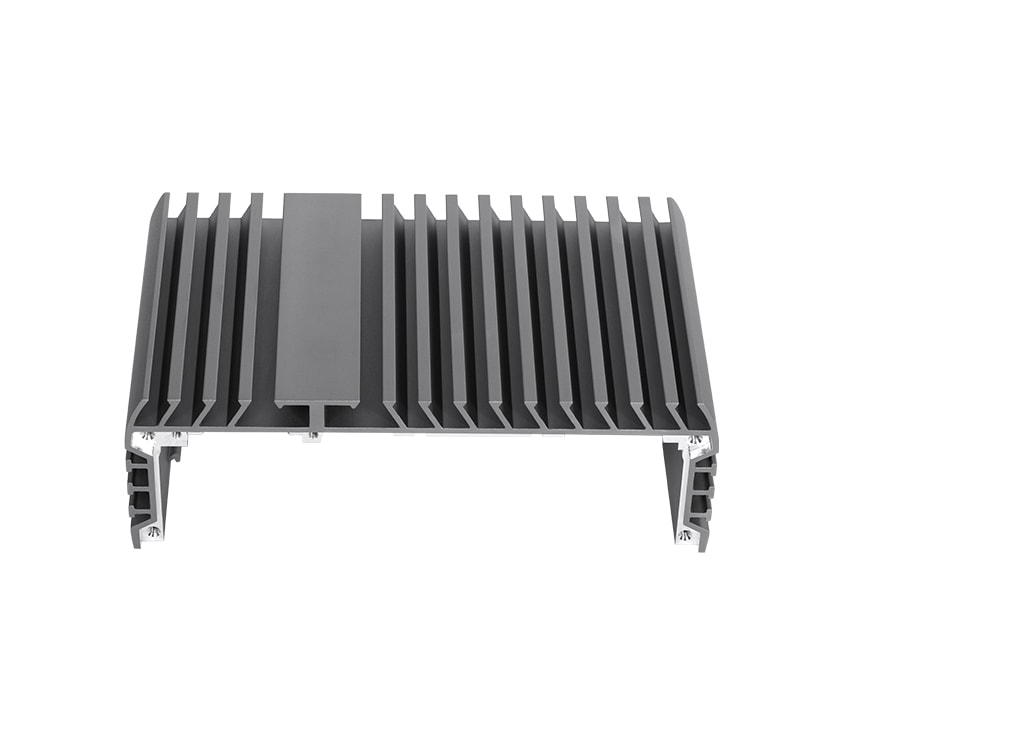

Aluminum Heat Spreaders and Extruded Heat Sinks

Our aluminum heat spreaders and extruded heat sinks are designed to distribute heat evenly and enhance cooling efficiency. With precise design and manufacturing, these heat sinks meet the cooling needs of high-power devices and are suitable for a wide range of industrial and electronic applications.

Aluminum Turned and Zip-Fin Heat Sinks

Our turned heat sinks and zip-fin heat sinks are made from high-quality aluminum and precisely machined to provide efficient cooling solutions. By increasing the surface area and optimizing heat dispersion, they are suitable for various demanding cooling situations.

Aluminum Stamped Heat Sinks and Accessories

Our stamped heat sinks and related

accessories

fully utilize aluminum's thermal conductivity and formability to offer economical and efficient cooling solutions. These products are designed for lightweight, high-efficiency cooling needs and are suitable for a variety of commercial and industrial applications.

Through continuous technological innovation and in-depth research into aluminum's thermal properties, we are committed to providing comprehensive aluminum cooling solutions to help our customers overcome cooling challenges, enhancing equipment performance and reliability.

In the field of thermal management technology, continuous technological innovation and a deep understanding of customer needs are key drivers of industry progress. Our company is committed to providing customized cooling solutions through technological innovation to meet the unique demands of customers in various application scenarios. Our series of aluminum heat sinks not only demonstrates the exceptional performance of aluminum in thermal applications but also reflects our capability for technological innovation.

Our R&D team constantly explores new technologies aimed at enhancing thermal efficiency and overall system performance. By employing advanced design software and simulation tools, we can precisely predict the performance of heat sinks during the product design phase, ensuring optimal results in actual applications. Additionally, we research new aluminum alloys and surface treatment technologies to further improve the thermal conductivity and durability of our heat sinks.

We understand that each project has its unique requirements. Therefore, in addition to offering a standard product line, we place a significant emphasis on the importance of customization services. Whether facing special environmental conditions, applications with strict size constraints, or high-performance systems seeking ultimate thermal efficiency, our team of engineers can provide personalized design and solutions. From initial concept discussions to the final product delivery, we work closely with our customers to ensure that the final cooling solution fully meets their expectations and requirements.

Looking to the future, we will continue to dedicate ourselves to research and development in thermal technology, exploring more innovative cooling solutions. We believe that through continuous technological innovation and optimization, we can provide our customers with more efficient and reliable thermal products. Whether improving existing technologies or developing entirely new solutions, we will spare no effort to meet market demand and advance the entire field of thermal technology.

Our series of aluminum heat sinks are the best testament to our commitment to technological innovation and customer service. We look forward to collaborating with more customers to explore the future of efficient cooling. If you are interested in our products or customization services, please visit our website or contact our sales team directly; we will be more than happy to serve you.

By continuing to use the site you agree to our privacy policy Terms and Conditions.