News

Site Editor

Site

/uploads/image/658e1b5398ef3.png

As global efforts toward sustainability and energy efficiency increase, governments worldwide are implementing stricter environmental regulations.

Site

/uploads/image/658e1b5398ef3.png

As global efforts toward sustainability and energy efficiency increase, governments worldwide are implementing stricter environmental regulations.

The Impact of Global Environmental Policies on the Thermal Management Industry

Views: 176

Author: Site Editor

Publish Time: 2025-03-21

Origin: Site

As global efforts toward sustainability and energy efficiency increase, governments worldwide are implementing stricter environmental regulations. These policies aim to reduce carbon emissions, improve energy efficiency, and minimize environmental impact. The thermal management industry, which plays a crucial role in electronics and industrial applications, is directly affected by these regulations. From material selection to manufacturing processes and product design, companies must adapt to meet evolving environmental standards while maintaining competitiveness.

Key Environmental Policies Affecting the Industry

Several global environmental regulations have a direct impact on the thermal management industry:

-

RoHS (Restriction of Hazardous Substances Directive) – Limits the use of harmful substances like lead, cadmium, and mercury in electronic products, pushing manufacturers to use environmentally friendly soldering materials.

-

REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) – Regulates chemical components in thermal management products, requiring transparency and restrictions on harmful substances.

-

WEEE (Waste Electrical and Electronic Equipment Directive) – Promotes recyclability and sustainability, encouraging manufacturers to consider the environmental impact of their products throughout their lifecycle.

-

Carbon Neutrality and Emission Regulations – Many countries have set carbon reduction targets, compelling manufacturers to lower their carbon footprint by adopting energy-efficient production methods.

The Impact on Thermal Management Materials

Environmental regulations have significantly influenced material selection in the thermal management industry:

-

Elimination of Lead-Based Soldering – Traditional lead soldering is being replaced with lead-free and low-temperature soldering techniques to reduce environmental harm.

-

Rise of Eco-Friendly Metals – Materials like aluminum, magnesium alloys, and copper-graphite composites are becoming more popular as alternatives to high-pollution metals such as beryllium copper.

-

Use of Recyclable Materials – Manufacturers are increasingly using recycled aluminum and biodegradable composites to reduce material waste and carbon emissions.

Green Manufacturing Processes

To comply with environmental regulations, companies are shifting toward more sustainable production methods:

-

Precision CNC Machining – Improves material utilization, reduces waste, and lowers energy consumption.

-

Cold Extrusion Technology – Replaces traditional high-energy forging methods to minimize carbon emissions.

-

Water-Based Cleaning Processes – Reduces volatile organic compound (VOC) emissions, making manufacturing more environmentally friendly.

-

Green Supply Chain Management – Optimizes material sourcing and production processes to reduce overall energy consumption and emissions.

Design Innovations for Energy Efficiency

To meet environmental requirements, thermal management products are evolving with improved efficiency:

-

High-Thermal Conductivity Materials – Advanced materials like graphite and vapor chambers help improve heat dissipation while reducing fan energy consumption.

-

Waste Heat Recovery (WHR) Technology – Captures and reuses excess heat from industrial processes, increasing energy efficiency and reducing emissions. For example, data centers can use liquid cooling technology to recover waste heat for building heating or electricity generation.

-

Smart Thermal Management Systems – Integrating temperature sensors and variable-speed cooling systems enables dynamic cooling, optimizing energy efficiency and reducing unnecessary power usage.

Challenges and Opportunities in the Green Transition

While environmental regulations pose challenges, they also open new doors for innovation and growth:

-

Opportunities – The demand for green thermal management solutions is rising, encouraging innovation in phase-change cooling, liquid cooling, and advanced heat dissipation materials. Companies investing in sustainable solutions can gain a competitive edge in the high-end market.

-

Challenges – Compliance costs are increasing, and traditional manufacturing processes are becoming obsolete. Companies must invest in green technologies and ensure their supply chains meet international environmental standards.

Conclusion: A Sustainable Future for Thermal Management

Environmental policies are reshaping the thermal management industry, driving it toward lower-carbon, energy-efficient, and sustainable solutions. Companies must proactively adopt eco-friendly materials, optimize manufacturing processes, and improve thermal efficiency to comply with regulations and stay competitive.

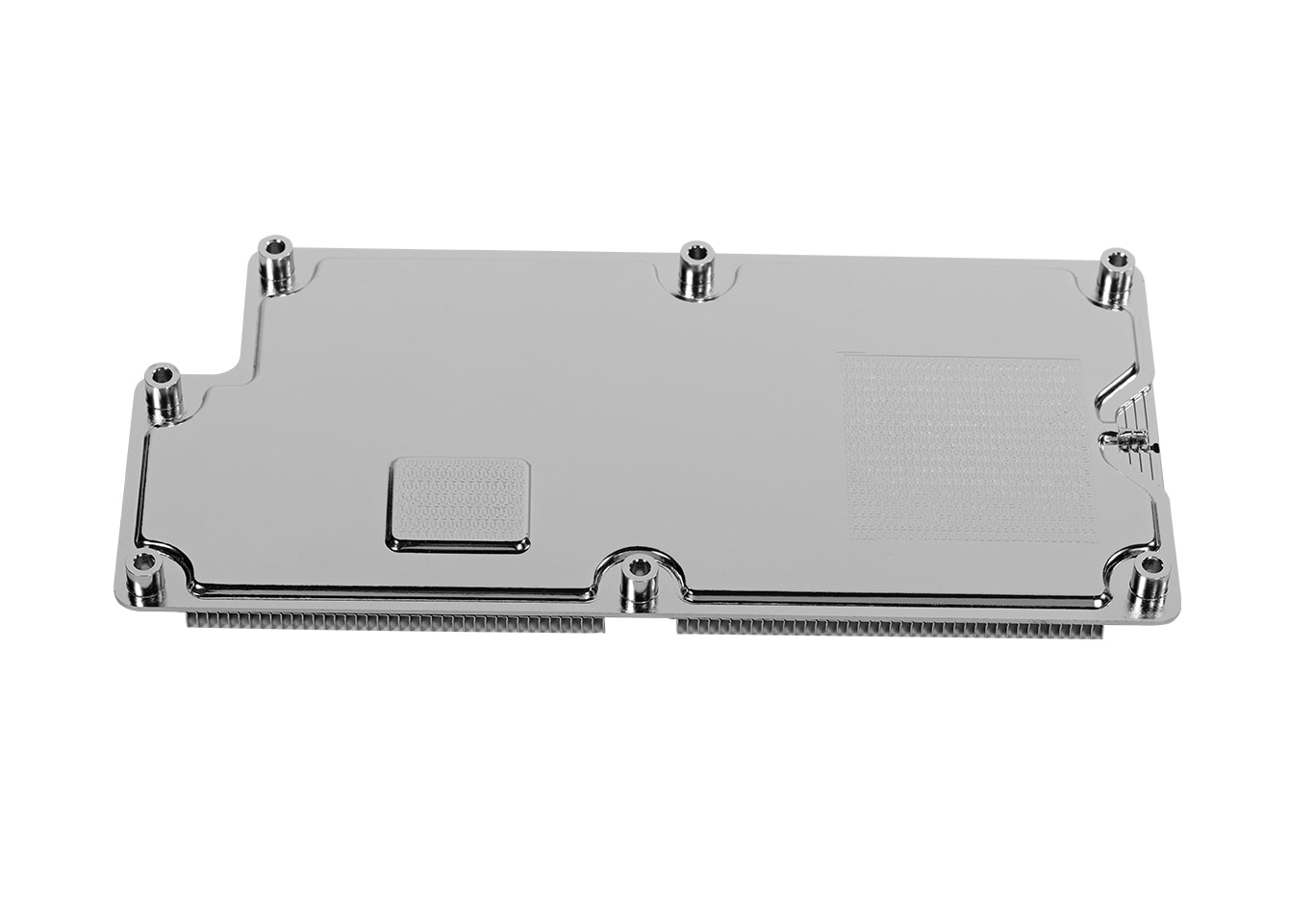

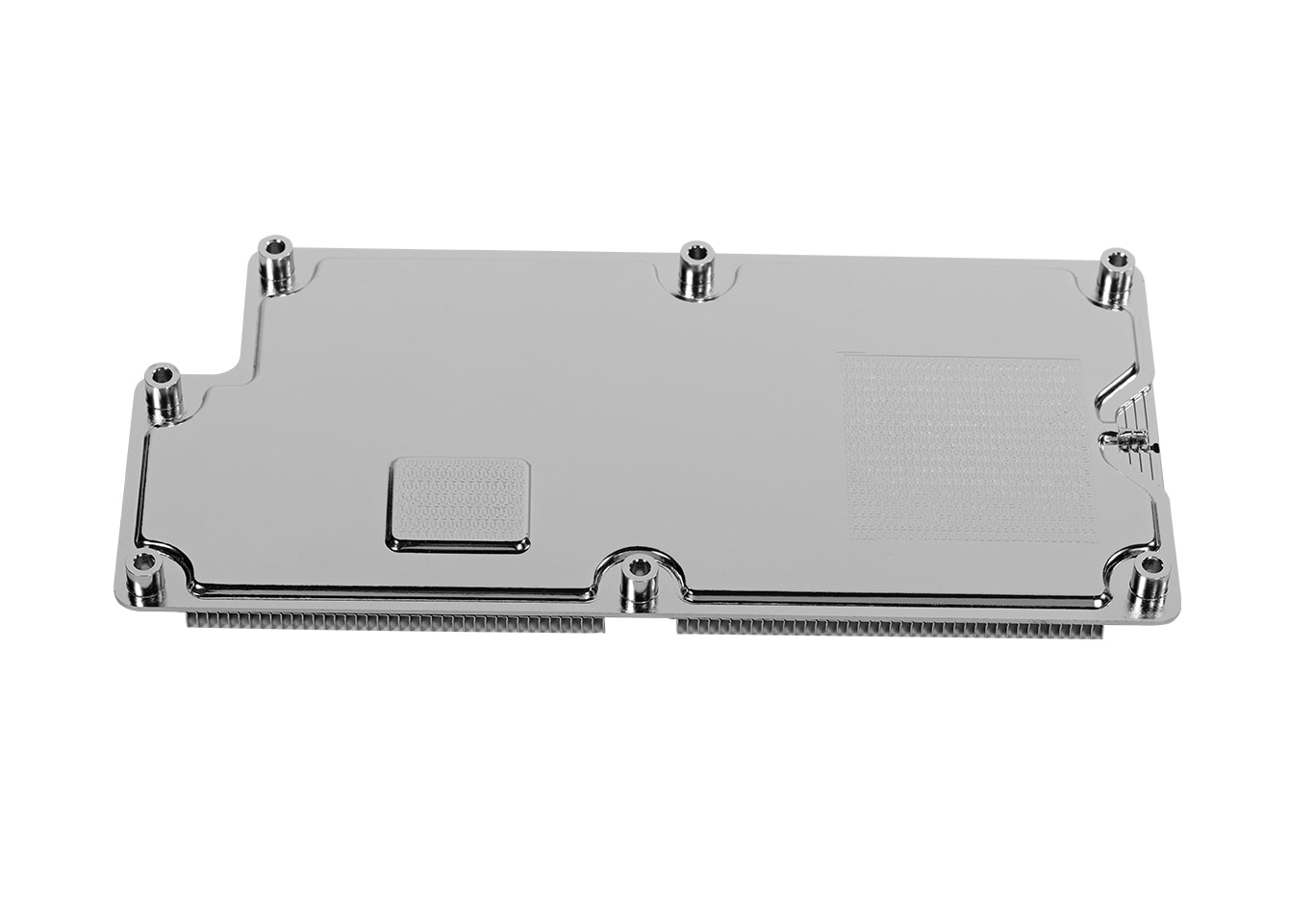

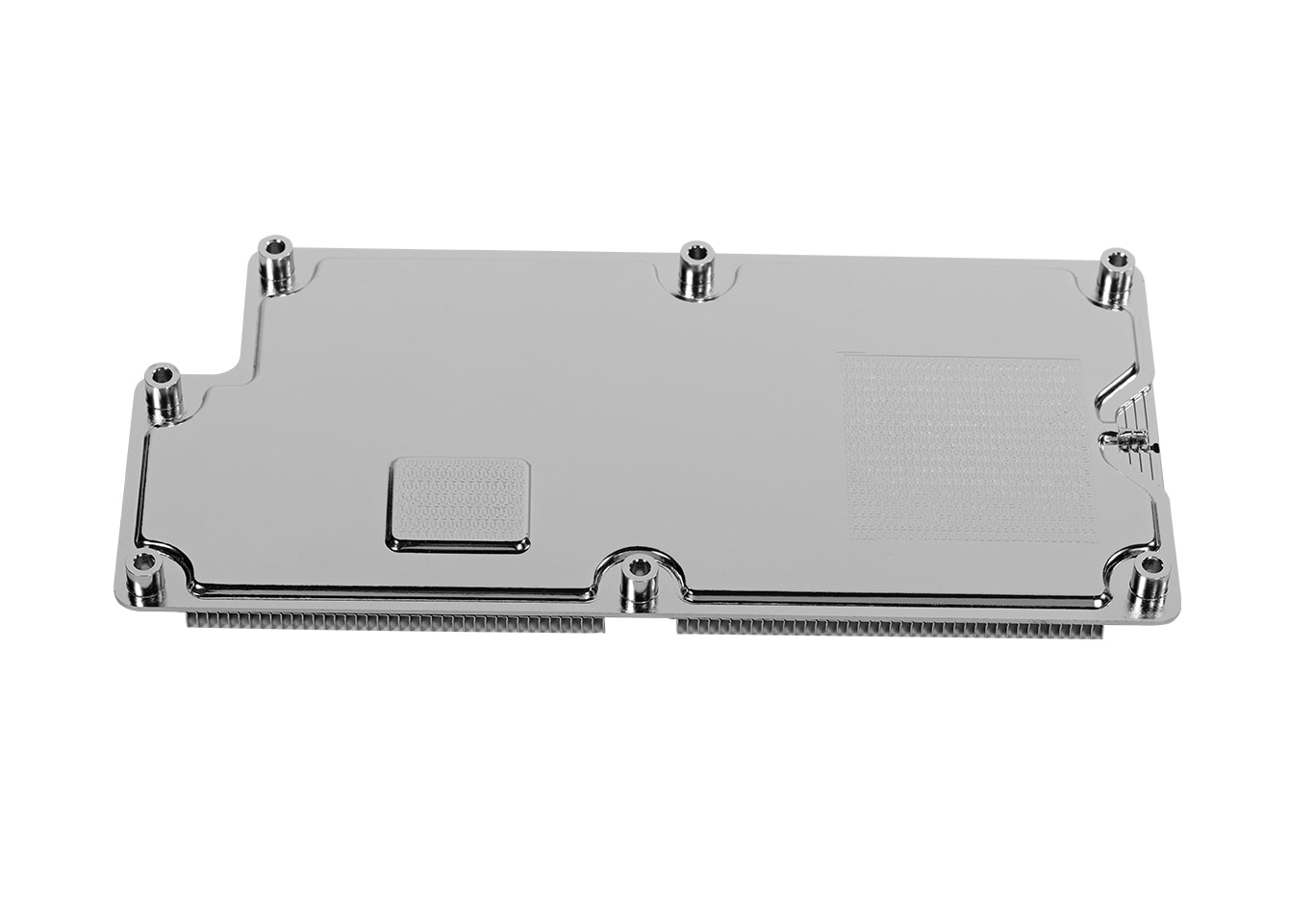

Enner Electronic Technology specializes in developing high-performance thermal management solutions that meet global environmental standards. Our products, including heat pipes, vapor chambers, and CNC heat dissipation components, help businesses achieve energy efficiency and sustainability. Contact us today to explore eco-friendly thermal solutions for your applications!