Heat sinks are one of the most essential components in cooling electronic equipment. For any heat source that cannot be properly cooled by its own conduction cooling and needs to be cooled more efficiently than a heat sink, a heat sink is required to remove the heat from the source and dissipate it by more optimized conduction or convection. This article describes the most popular passive heat sink types , integration, customization, and how to choose the right fabrication and fin type for your application.

Plate level radiators can be stamped or extruded. Stamped heatsinks are made from sheet metal that undergoes a progressive stamping process, in which detail and functionality are added to each metal stamping as it passes through the stamping die. Stamped heat sink geometries are designed for specific electronic package types to ensure optimized fit and function on the PCB. These heat sinks can be passive or active, based on the addition of fans, which are typically used to increase airflow throughout the board or system.

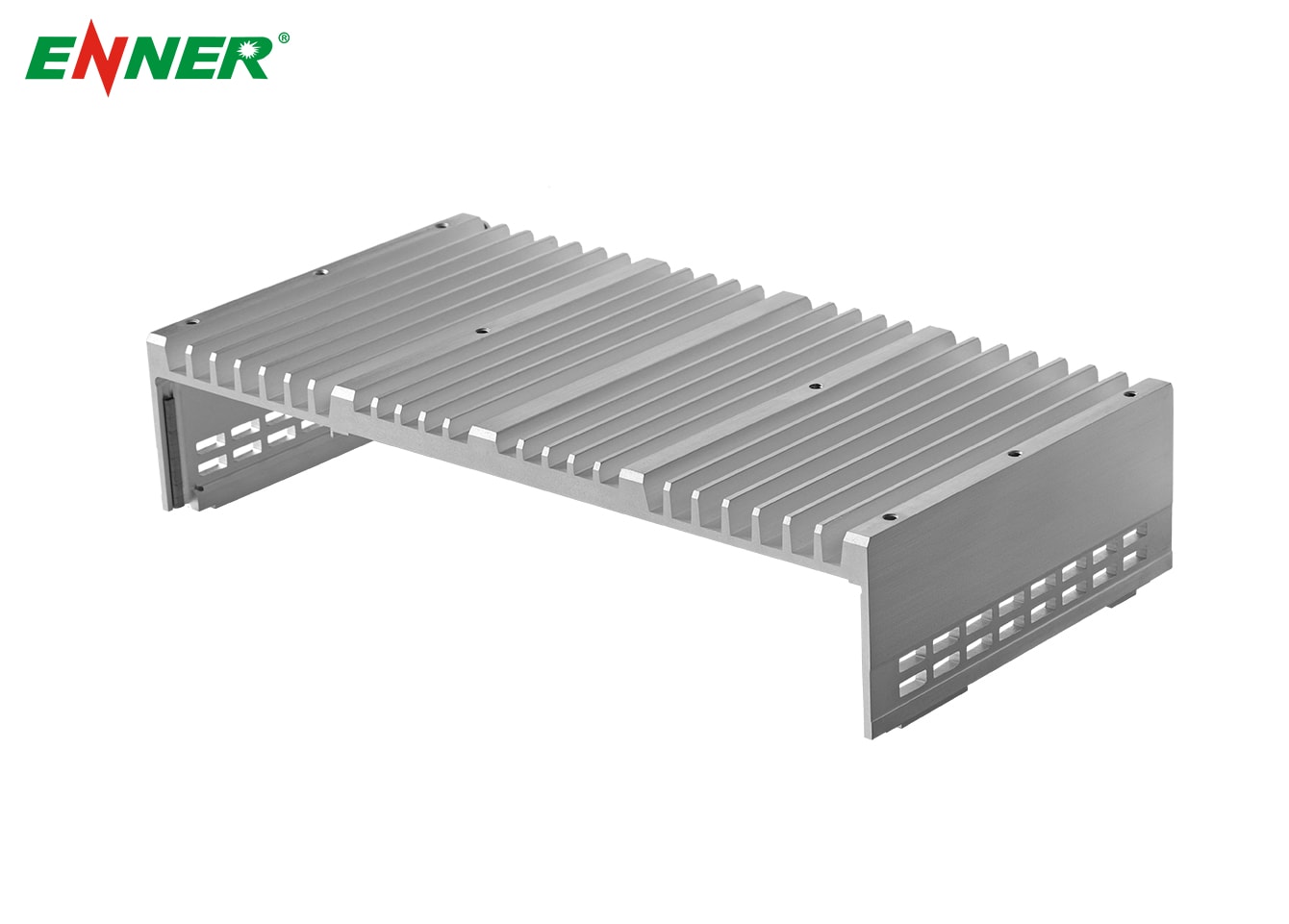

Extruded aluminum is one of the most popular and cost-effective manufacturing methods. Extruded heat sinks vary in size depending on the application, being smaller for board level applications and larger for medium power applications. They can be designed for passive or active cooling depending on fin shape and spacing. Board-level extruded heat sinks are common in packages such as BGAs and FPGAs.

Choosing the right extruded heat sink depends heavily on the desired form factor. Extruded heat sinks are made by creating a profile die that determines the fin density, pitch and length, as well as the base height and width. Softened aluminum is pushed into the die to form a long bar, called a raw bar, with the same profile and dimensions as the die. The bar is then cut into smaller standard shaped bars/rectangles or custom lengths. These are further machined and finished to create customized heat sinks. The process is fast, cost-effective and scalable; which is why many people consider extruded radiators first when looking for a solution.

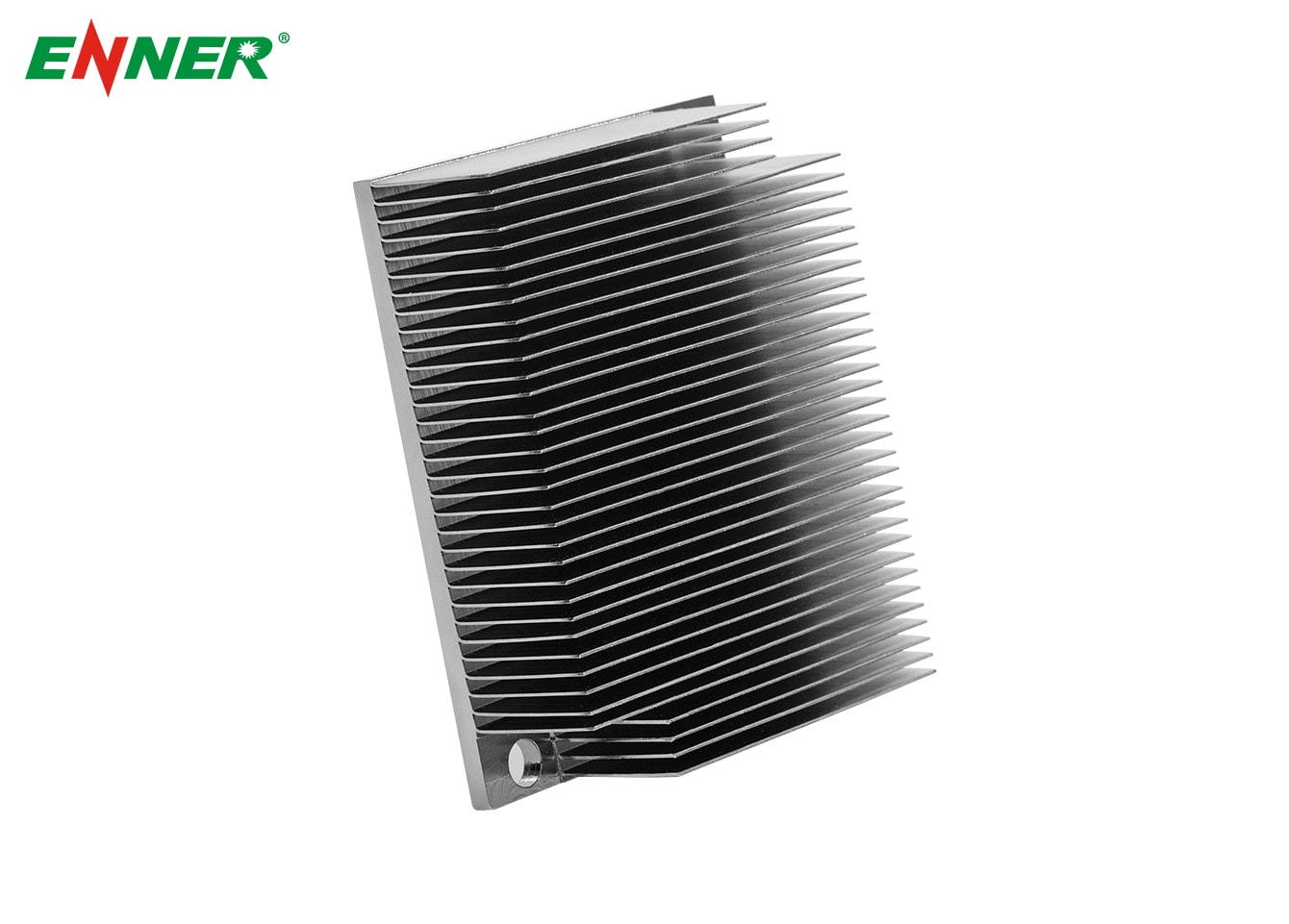

Turning is a method of processing fabricated materials made from a single piece of metal in which layers are partially sliced from the top portion of the base into thin slices. These layers are folded up to be perpendicular to the base and the process is repeated periodically to create the fins. The one-piece construction reduces thermal resistance because there are no seams or materials between the fins and the base. The process also allows for high fin densities and thin fin geometries, resulting in greater radiator surface area and higher heat transfer.

Unlike extruded radiators, turned-fin radiators are not dependent on tooling and multiple steps; instead, they utilize a single cutting tool, which reduces tooling costs, improves design flexibility, and speeds prototyping.

Bonded fin heat sinks are two-piece assemblies consisting of an extruded or machined base with recesses or slots and fins that are attached to a thermally conductive adhesive (usually epoxy or solder). To improve structural integrity and thermal performance, these structures are sometimes brazed to strengthen the thermal and mechanical bond.

The fins are usually stamped from a coil or cut from thin sheet stock, while the base is usually extruded, die-cast or machined. The base may also include additional thermal integration, such as embedded heat pipes or heat equalizing plates, to achieve higher performance. By supporting more and longer fins and additional customization, bonded radiators provide higher performance and greater surface area in a smaller footprint.

Zipper fin stacks are made from a series of individually stamped sheet metal fins that are folded and zipped together using an interlocking feature. Fin lengths and clearances vary depending on the stamping die. The fins can be closed to form a finned duct or left open for multi-directional airflow as required by the application. Fin stacks are typically welded, brazed, or epoxied to the radiator base or heat pipes for a complete thermal assembly. The connection of the top and bottom fins improves mechanical stability and makes the radiator more durable. Zippered fin stacks offer a high degree of design flexibility and can be used for highly integrated solutions using a range of technologies from recessed and transportable heat pipes and heat equalization panels to fans and large systems.

Folded fins are constructed by passing a sheet of metal through a folding process to create a variety of geometric shapes with greater surface area. Although these fins can be used in a range of technologies, including liquid-cooled panels; they are often bonded or brazed to a base to form a heat sink.

Die-cast radiators are one-piece constructions. They are primarily produced in high volumes for applications that are weight sensitive, require superior surface quality, or have highly complex geometries. These solutions are created by pouring a thermally conductive alloy into a custom mold of near-net shape, followed by light machining and finishing to obtain the final product.

By continuing to use the site you agree to our privacy policy Terms and Conditions.