News

Site Editor

Site

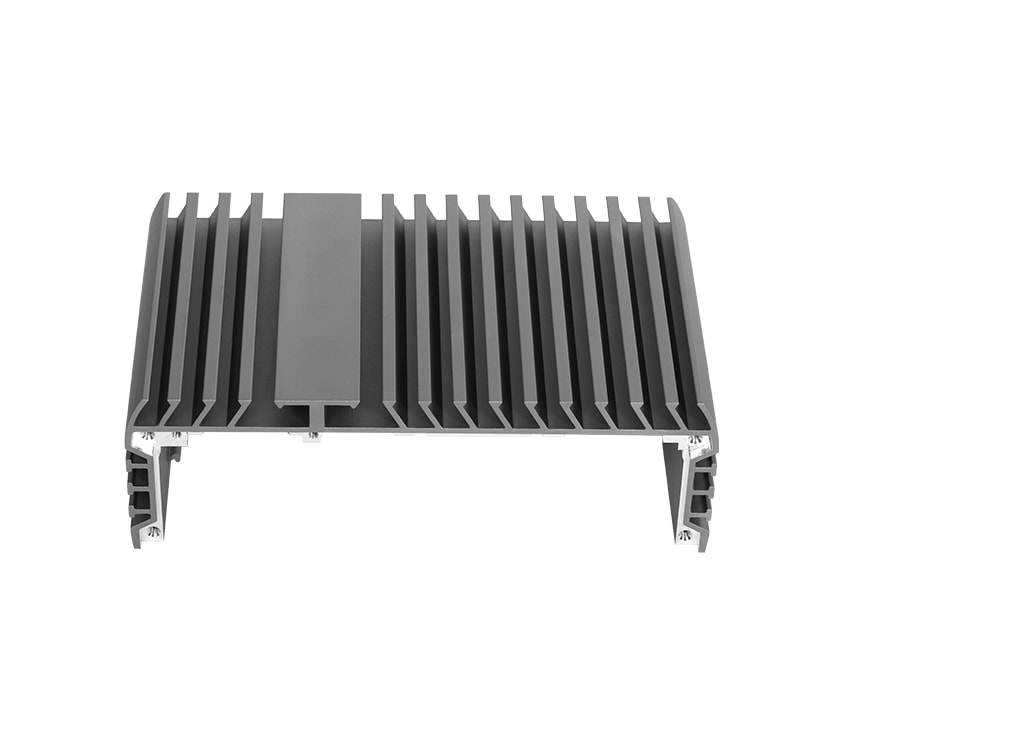

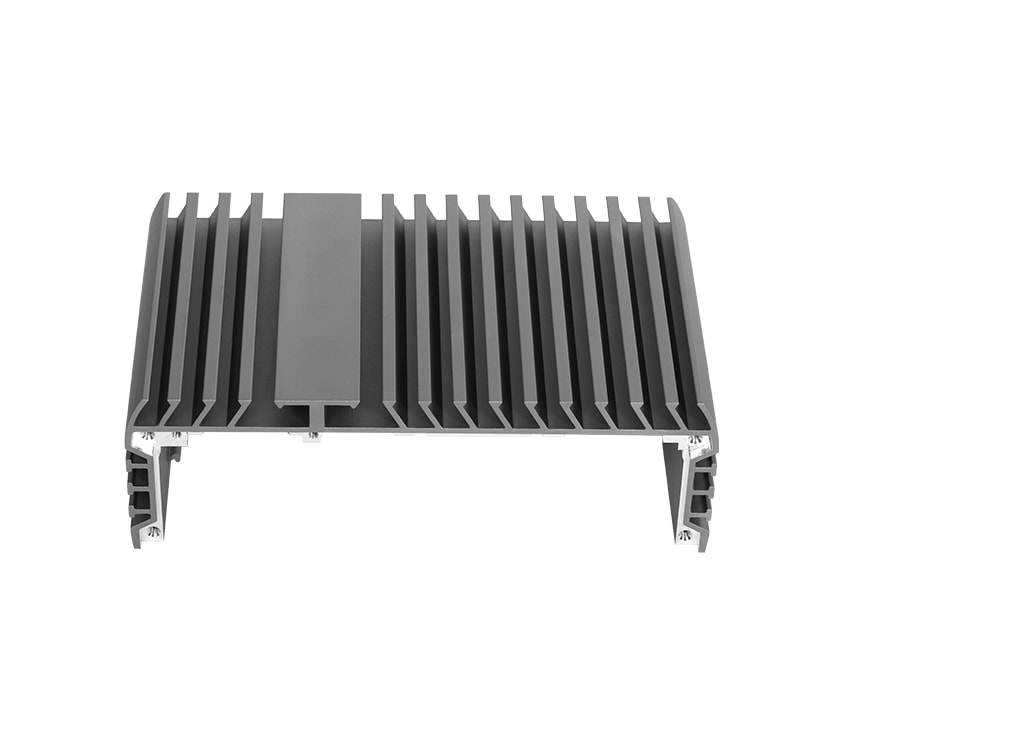

/uploads/image/658e1b5398ef3.png

Site

/uploads/image/658e1b5398ef3.png

Custom Cooling Solutions: Meet Your Unique Cooling Needs

Views: 571

Author: Site Editor

Publish Time: 2024-02-28

Origin: Site

In the ever-evolving landscape of technological advancements, the demand for effective heat dissipation solutions has become paramount. The phrase "Innovative Custom Heat Sink" encapsulates the essence of our journey – a journey dedicated to revolutionizing the way industries approach thermal management. As industries grapple with increasingly complex heat dissipation challenges, the need for tailored solutions has never been more critical. This introduction sets the stage for a discourse on the transformative power of customized heat sink services. Within the realm of heat dissipation, our commitment to innovation and customization emerges as a beacon of promise. This article delves into the intricacies of how Innovative Custom Heat Sink solutions are reshaping the narrative, offering unparalleled efficiency, and meeting the unique thermal demands across diverse sectors. Join us on this exploration of cutting-edge solutions that redefine the benchmarks of heat management in an era where innovation is not just a choice but a necessity.

Thermal Challenges

In the dynamic landscape of technological advancements, the demand for effective heat dissipation solutions has become more pressing than ever. Various industries grapple with diverse and increasingly complex thermal challenges that traditional methods struggle to address adequately.

Diverse Industry Challenges

-

The electronics industry faces a constant uphill battle as devices become smaller and more powerful. The escalating power densities in modern electronics generate substantial heat, necessitating innovative thermal management solutions. In parallel, the automotive sector undergoes a transformative shift with the rise of electric vehicles. This evolution introduces new thermal challenges, particularly in battery management and power electronics, demanding sophisticated heat dissipation techniques.

Limitations of Conventional Solutions

Conventional thermal management approaches, such as air cooling and basic heat sinks, encounter limitations when confronted with the demands of cutting-edge applications. The inherent constraints of these methods become evident as electronic devices and systems strive for higher performance levels in smaller form factors. Inadequate thermal management can lead to compromised functionality, reduced component lifespan, and increased energy consumption – factors that are increasingly unacceptable in the pursuit of technological excellence.

Case Studies on Thermal Constraints

Examining real-world scenarios underscores the critical nature of thermal constraints. Instances where conventional solutions have fallen short – causing devices to overheat and malfunction or impeding the efficiency of automotive systems in extreme conditions – emphasize the urgency for innovative approaches. These case studies provide a tangible understanding of the challenges at hand and set the stage for the exploration of more effective solutions.

The Call for Customization

The diverse and evolving nature of thermal challenges necessitates a departure from generic, one-size-fits-all solutions. Customization emerges as the linchpin for overcoming thermal obstacles effectively. Tailoring heat dissipation solutions to the unique demands of specific industries and applications becomes imperative. This section serves as a prelude to the exploration of Innovative Custom Heat Sink solutions, shedding light on their pivotal role in revolutionizing thermal management strategies to meet the distinct needs of today's technological landscape.

The Value of Customized Heat Dissipation Services

In the intricate realm of thermal management, the paradigm has shifted towards customization as the linchpin for overcoming diverse and complex challenges. The value inherent in Innovative Custom Heat Sink services lies in their ability to provide tailored solutions that transcend the limitations of generic approaches.

Defining Customization's Scope and Definition

Customization is not merely a buzzword but a strategic imperative. It involves a meticulous analysis of the unique thermal demands of each industry and application, steering away from the one-size-fits-all mindset. In essence, customization extends beyond product modification; it encompasses a comprehensive understanding of specific thermal challenges, ensuring solutions that align seamlessly with the intricacies of each scenario.

Flexibility and Adaptability

The value of customization becomes apparent in its unparalleled flexibility. Off-the-shelf solutions may struggle to adapt to the evolving landscape of thermal requirements. Customized heat dissipation services offer a dynamic approach, allowing for adjustments in design, materials, and configurations based on the specific needs of the application. This adaptability ensures that thermal management solutions grow alongside technological advancements and industry-specific changes.

Optimizing Thermal Performance

Tailored solutions are engineered with precision to optimize thermal performance. The ability to factor in specific thermal conductivity requirements, form factors, and spatial constraints ensures that the heat dissipation solution is not only effective but also efficient. This optimization results in enhanced performance, increased longevity of components, and a reduction in energy consumption – all crucial factors in achieving sustainable and high-performance thermal management.

Addressing Industry-Specific Challenges

Different industries harbor unique thermal challenges, and customization is the key to addressing them effectively. Whether it's the miniaturized world of electronics or the rugged conditions of automotive applications, customized solutions can be fine-tuned to meet the exacting demands of each sector. This targeted approach ensures that the thermal management strategy is not only effective but also tailored to the intricacies of the industry in question.

Enner's Customized Heat Dissipation Services

Welcome to Enner, your trusted partner in redefining thermal management through cutting-edge solutions. With a rich background in engineering and innovation, we bring a wealth of expertise to the realm of customized heat dissipation services. At Enner, we understand that addressing thermal challenges requires a nuanced and individualized approach.Enner's customization journey begins with a meticulous examination of your unique thermal requirements. Our process involves comprehensive consultations to understand the intricacies of your industry and application. From there, our expert team collaborates to devise tailored solutions that align seamlessly with your specific needs. We go beyond modifying existing products; we craft bespoke solutions engineered to perfection.

At the heart of Enner's customized heat dissipation services lies our technological prowess. Our team of skilled engineers leverages the latest advancements and innovations to create solutions that not only meet but exceed industry standards. From utilizing cutting-edge materials to embracing innovative design concepts, Enner stands at the forefront of thermal management ingenuity.One of the hallmarks of Enner's approach is flexibility. We understand that thermal demands evolve, and our solutions are designed to adapt. Whether it's adjusting designs, materials, or configurations, our customized approach ensures that your thermal management solution remains agile, catering to the changing landscape of your industry.

Client Case Studies

In the dynamic realm of thermal management, Enner has left an indelible mark through real-world solutions that transcend theoretical excellence. Our commitment to customized heat dissipation services finds its true testament in the success stories of our diverse clientele.

Embedded within the electronics industry, a multinational corporation faced daunting challenges in maintaining optimal operating temperatures for their compact yet powerful devices. Enner's engineers undertook a comprehensive analysis of the client's thermal requirements, customizing a solution that not only exceeded expectations but also enhanced overall device performance. The tailored heat dissipation strategy not only mitigated overheating issues but also contributed to an extended lifespan of critical components, resulting in a tangible increase in product reliability.

In the automotive sector, a leading electric vehicle manufacturer grappled with intricate thermal challenges in their battery management systems. Enner's specialized approach addressed these complexities head-on, delivering a customized solution that not only optimized thermal performance but also significantly increased energy efficiency. The result was a seamless integration of our heat dissipation solution into their electric vehicles, ensuring reliable and efficient battery management in even the most demanding conditions. These client case studies underscore Enner's prowess in translating customization into tangible success, setting the stage for a transformative partnership with businesses across diverse industries.

Exploring Industry-Specific Thermal Success Stories

By delving into customized heat dissipation success stories across diverse industries, we gain valuable insights into the unique thermal demands and trends that shape each sector. This in-depth exploration serves as a window into the intricacies of thermal challenges, shedding light on why customization is paramount in addressing industry-specific needs.

In the electronics industry, where devices are shrinking in size while amplifying in power, tailored heat dissipation solutions have proven crucial. Our case studies reveal how customization not only prevents overheating issues but also enhances overall device performance, ensuring reliability and longevity. Similarly, the automotive sector experiences distinctive thermal challenges, particularly in electric vehicles. Through specialized approaches, our customized solutions optimize thermal performance, contributing to increased energy efficiency in battery management systems.

Understanding these industry-specific thermal nuances is paramount, highlighting the pivotal role of customization in navigating challenges effectively. It provides readers with a clearer perspective on why tailored solutions are indispensable, offering the flexibility needed to adapt to evolving thermal landscapes in their respective businesses.

The exploration of customized heat dissipation success stories underscores the importance of tailored solutions. As businesses face evolving thermal challenges, the flexibility offered by customization becomes a strategic advantage. This comprehensive understanding not only empowers businesses to navigate the complexities of thermal management but also positions Enner as the trusted partner in achieving thermal excellence. With a wealth of expertise and a proven track record, we invite our readers to embark on a transformative journey. Let Enner be your ally in crafting customized solutions that not only meet but exceed industry-specific thermal demands, paving the way for successful transactions and sustained business success.