In the continuous development of the manufacturing industry, CNC numerical control processing technology, as a key manufacturing process, has gradually become an important support for production in various industries. CNC (Computer Numerical Control) CNC machining is favored by manufacturing companies for its high precision and high efficiency. This article will deeply explore the principles of CNC machining parts and analyze the technical secrets behind it, hoping to provide readers with a deeper understanding and understanding.

Basic principles of CNC machining

The basic principle of CNC machining originates from the "Numerical Control" in its name, which is to control the movement of the machine tool through digital instructions from the computer to achieve precision machining of the workpiece. First, the designer creates a three-dimensional model of the product through CAD (Computer-Aided Design) software, and then converts this design into a CNC program. A CNC program contains a series of instructions that tell the machine tool how to move, cut, and where to stop. This digital instruction not only improves the accuracy of processing, but also greatly improves production efficiency.

The key to CNC machining lies in its control system. The control system receives instructions from the CNC program and then converts them into electrical signals to accurately control the relative movement of the tool and workpiece through the motor and servo system. This highly automated process enables CNC machining to not only complete complex processes in a short time, but also ensures the accuracy and consistency of each part. Through continuously upgraded control systems, manufacturers can better adapt to the processing needs of various complex products and provide solid support for industrial upgrading.

Overall, the core of the basic principles of CNC machining lies in digital control and high degree of automation, which enables manufacturing companies to respond to market demands more flexibly and efficiently, thus promoting the rapid development of the entire manufacturing industry.

Process advantages of CNC machining

CNC numerical control processing has become an indispensable part of modern manufacturing industry with its unique process advantages. First, its highly precise cutting capabilities produce parts with a consistency and precision that far exceeds the level of traditional hand or conventional machining. The direct benefits brought by this high precision are reduced scrap rates, improved product quality standards, and established an excellent brand image for the company.

Secondly, CNC machining has excellent ability to process complex shapes. Through flexible tool path control, CNC machine tools can easily cope with the processing needs of various complex-shaped parts, which often requires tedious equipment adjustments and manual operations in traditional processing. This flexibility not only improves production efficiency, but also provides designers with greater creative space and promotes innovation in product design and manufacturing.

In addition, the high degree of automation of CNC machining reduces the intervention of human factors and improves production efficiency and safety. Workers are only responsible for monitoring and maintaining the equipment, rather than manipulating the tools themselves, which effectively reduces labor intensity and improves the safety of the working environment.

The ultimate application of CNC machining in the medical and automotive industries

The excellent precision of CNC machining makes it play an irreplaceable role in fields such as the medical and automotive industries where parts have extremely high tolerances. In the manufacturing of medical devices, such as surgical instruments, artificial joints, etc., the precision of parts is extremely high. CNC machining can achieve micron-level cutting precision and control tolerances within an incredible 0.002mm range. This ultra-high precision provides a solid guarantee for the performance and reliability of medical devices and ensures the accuracy and safety of surgery.

In the automotive industry, the manufacturing of key components such as engine parts and transmission systems also has very strict tolerance requirements. CNC machining uses digital control to accurately move the machine tool to the micron level, reaching or even exceeding the industry standard tolerance level of 0.002mm. This not only ensures the interchangeability and stability of auto parts, but also improves vehicle performance and fuel efficiency. The application of CNC machining in the automotive industry has promoted the continuous innovation of automotive technology and provided a solid foundation for the sustainable development of the automotive industry.

Overall, CNC machining plays a key role in precision manufacturing in the medical and automotive industries, and its superior tolerance control provides highly reliable quality assurance for products in these fields.

The future outlook of CNC machining

The continuous evolution and innovation of CNC machining technology has brought unprecedented development opportunities to the manufacturing industry. With the widespread application of advanced materials and the continuous maturity of digital technology, CNC numerical control processing will further expand its application fields. In the future, we can expect to see more applications of CNC machining in aerospace, electronics, new energy and other fields.

In the aerospace sector, there is a growing demand for lightweight, high-strength components. CNC numerical control processing can not only meet the requirements for complex shapes and high precision of parts, but also adapt to the processing of various advanced materials, providing key support for the manufacturing of aerospace devices. This will promote the rapid development of aerospace technology and make aerospace devices lighter and stronger.

In the electronics field, CNC numerical control processing will play an increasingly important role in the manufacturing of microelectronic devices and semiconductor components. Its high precision and efficiency will promote the improvement of the manufacturing level of electronic products and provide a solid foundation for the rapid development of information technology.

At the same time, CNC numerical control processing also has broad application prospects in the field of new energy. Solar panels, wind turbine parts and other components that require extremely high precision and complexity can be efficiently produced through CNC machining, providing reliable support for the promotion and application of new energy technologies.

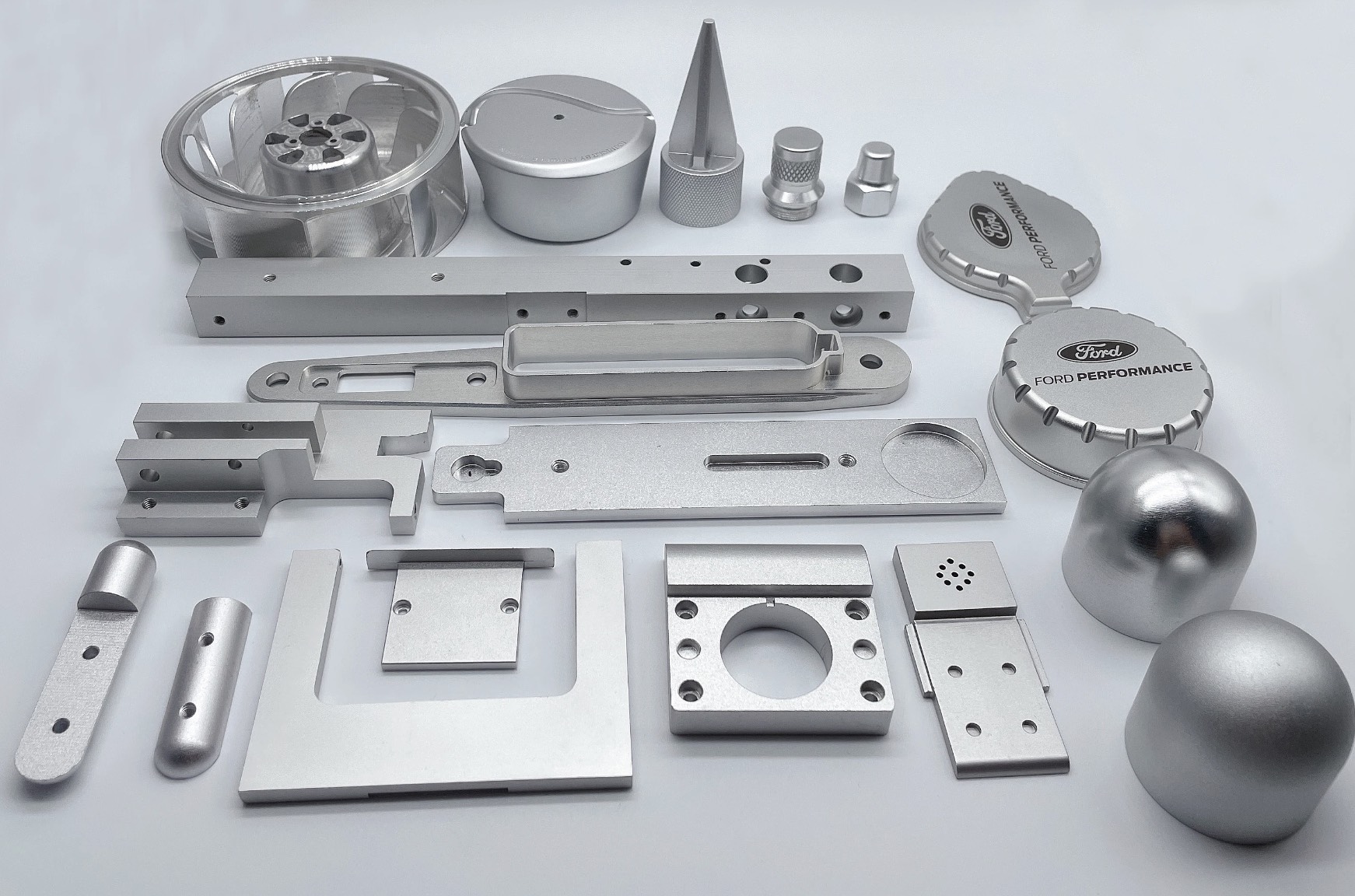

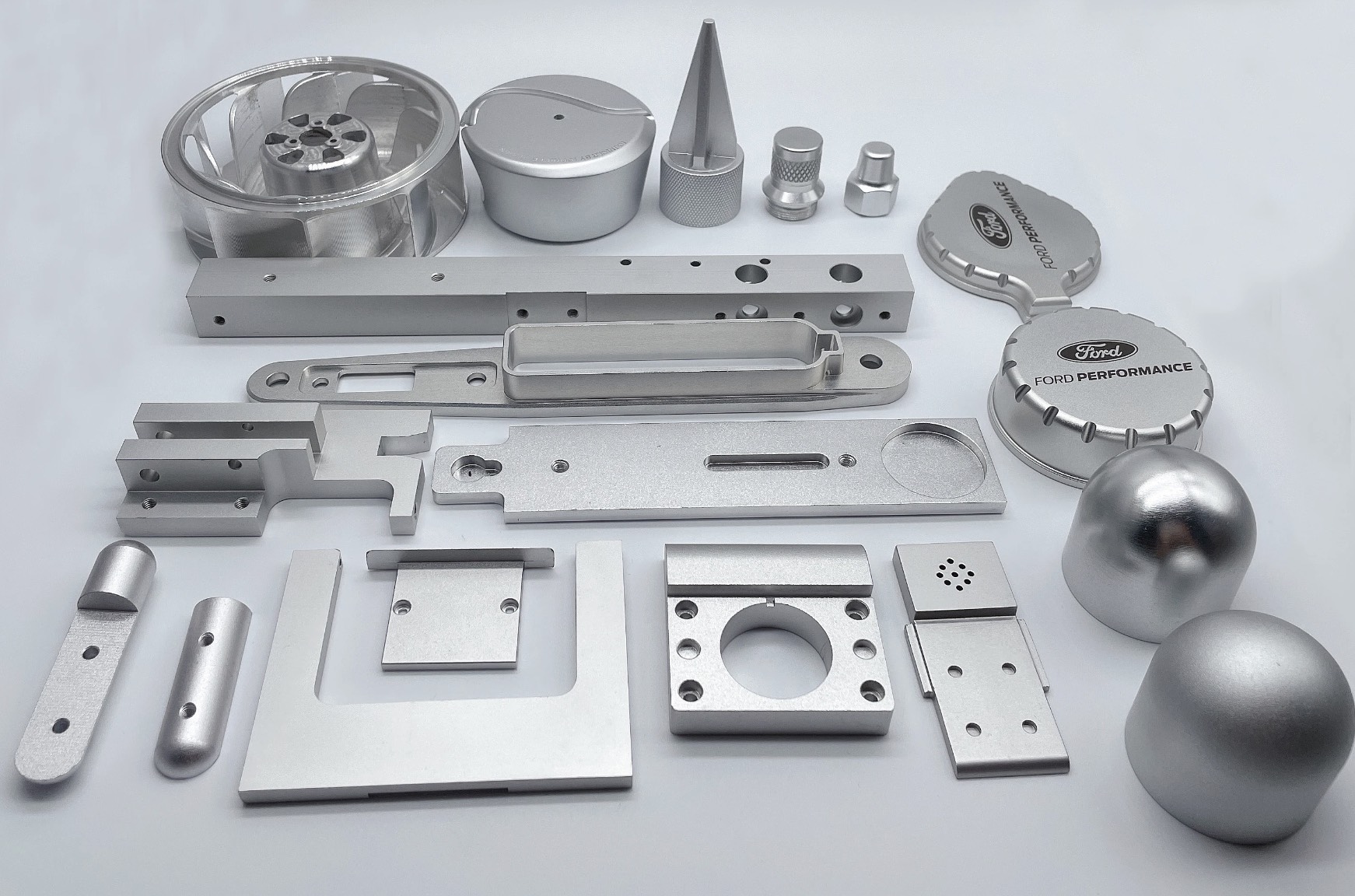

Enner's CNC machining solutions

As CNC machining technology continues to evolve, the manufacturing industry seeks professional partners to achieve high-quality, high-efficiency production. With its professional experience and technical strength in the field of CNC machining, Enner has become the ideal choice for enterprises in this fierce market.

Enner is committed to providing comprehensive CNC processing solutions to customers in various industries. We have advanced CNC processing equipment and an experienced and skilled team. Whether it is medical equipment, automotive parts, aerospace, or electronic products, Enner can meet customers' stringent requirements for precision machining.

Our CNC machining services offer exceptional flexibility and can adapt to the processing of a variety of materials, including metals, plastics, composites, and more. Moreover, we pay attention to every detail and are committed to providing customers with highly customized solutions to ensure that every part meets the customer's precise requirements.

In addition to technical strength, Enner Company also emphasizes high efficiency and timely delivery. We understand our customers' urgent needs for production cycle time, so while ensuring quality, we also strive to minimize the processing cycle. This not only improves production efficiency, but also better meets customers' market needs.

Choosing Enner as a CNC processing partner means choosing first-class technology, a professional team and an efficient production process. We are willing to work with companies from all walks of life to jointly promote innovation and development in the manufacturing industry and create greater value for customers.