A computer's CPU (central processing unit) is often prone to overheating because some of its components overheat, posing risks to the entire computer's functionality.

In this blog, you'll learn how heat sinks help protect your computer's CPU from overheating, ensuring maximum efficiency and the protection of critical parts and components.

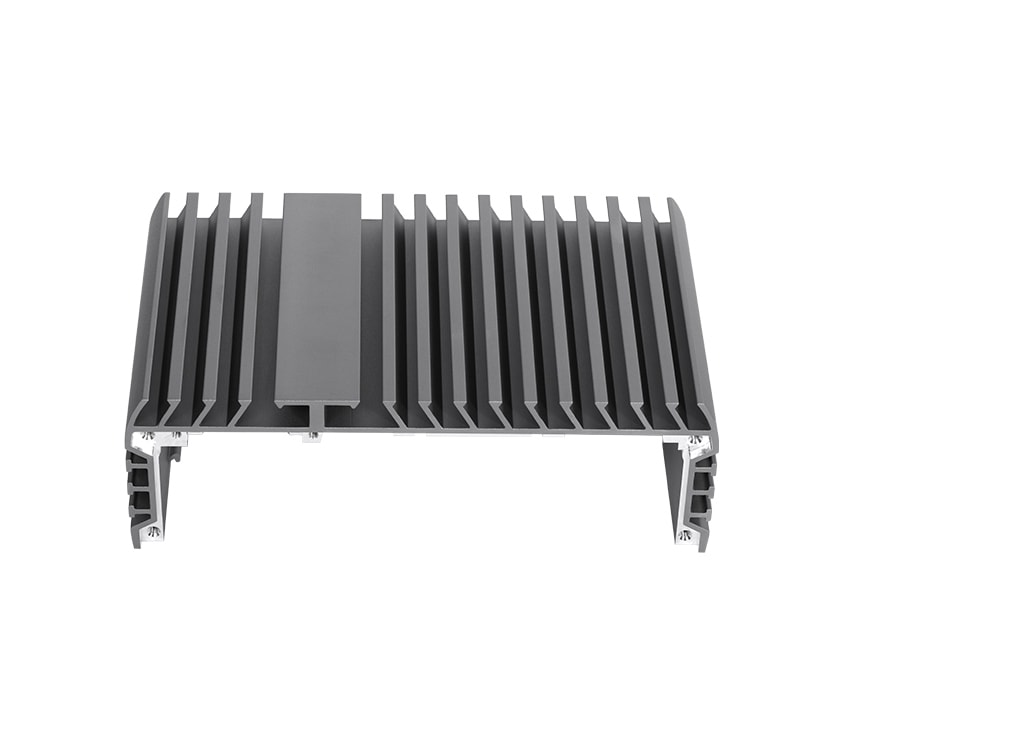

A heat sink is a passive thermal management device used to dissipate heat away from a hot surface or electronic component to maintain optimal operating temperatures. It is typically made of a thermally conductive material such as aluminum or copper and is designed with fins or other structures to increase surface area and facilitate heat transfer to the surrounding environment.

Heat sinks are commonly used in electronic devices such as computers, amplifiers, and LED lights to prevent overheating of components such as processors, transistors, and LEDs. When electronic components operate, they generate heat, which can degrade performance and reduce lifespan if not properly managed. Heat sinks absorb this heat and transfer it away from the component,

allowing it to dissipate into the surrounding air through convection.

Heat sinks come in various shapes and sizes depending on the application and thermal requirements. Some heat sinks are simple metal plates, while others have intricate designs with fins, heat pipes, or even liquid cooling systems for more efficient heat dissipation. Overall, heat sinks play a crucial role in maintaining the reliability and performance of electronic devices by managing heat effectively.

The primary purpose of a heat sink is to dissipate heat away from a hot surface or component, usually found in electronic devices, to prevent overheating and maintain optimal operating temperatures. Electronic components, like CPUs, GPUs, power transistors, and LED lights, generate heat during operation. If this heat is not efficiently managed, it can lead to performance degradation, reduced lifespan, or even failure of the component or device.

A heat sink provides a pathway for the heat to transfer away from the component to the surrounding environment. Typically made of materials with high thermal conductivity, such as aluminum or copper, heat sinks absorb heat from the component and then disperse it into the air through convection. They are often designed with fins or other structures to increase the surface area, facilitating more effective heat transfer.

By effectively dissipating heat, heat sinks help to maintain the desired operating temperature range, ensuring optimal performance and reliability of electronic devices. In summary, the purpose of a heat sink is to keep electronic components cool and prevent them from overheating, thereby preserving their functionality and extending their lifespan.

A heat sink works through a process of heat transfer known as conduction and convection. Here's how it operates:

Conduction: When an electronic component, such as a CPU or GPU, generates heat during operation, it transfers this heat to the surface of the heat sink through direct contact. The heat sink is typically made of a material with high thermal conductivity, such as aluminum or copper. These materials efficiently conduct heat away from the hot component and distribute it throughout the heat sink.

Convection: Once the heat is transferred to the surface of the heat sink, convection comes into play. The heat sink is designed with fins, ridges, or other structures that increase its surface area. As the heated surface of the heat sink interacts with the surrounding air, the air molecules near the surface gain thermal energy and become less dense, causing them to rise. This movement of air creates a flow that carries heat away from the heat sink and into the surrounding environment.

By continuously absorbing heat from the electronic component and transferring it to the surrounding air, the heat sink effectively dissipates heat, keeping the component within its optimal operating temperature range. The efficiency of a heat sink depends on factors such as its material, design, surface area, airflow, and the temperature gradient between the component and the ambient environment. Ultimately, the goal of a heat sink is to prevent overheating and maintain the performance and reliability of electronic devices.

There are three types of heat sinks: passive, active, and hybrid.

Passive heat sinks rely on natural convection, meaning the ability of hot air to float causes the airflow generated across the heat sink, and they do not require secondary power or control systems to remove heat. But passive heat sinks are not as effective at removing heat from a system as active heat sinks.

Active heat sinks utilize forced air--commonly generated by a fan, blower, or even movement of the entire object--to increase fluid flow across the hot area.

This is like the fan in your personal computer turning on after your computer gets warm. The fan forces air across the heat sink, which allows more unheated air to move across the heat sink surface. This increases the total thermal gradient across the heat sink, allowing more heat to exit.

Hybrid heat sinks combine characteristics of both passive and active heat sinks. These configurations are less common, often using control systems to cool the system based on temperature requirements.

When the system operates at cooler levels, the forced air source is inactive, only cooling the system passively. Once the source reaches higher temperatures, the active cooling mechanism engages to increase the cooling capacity of the sink.

Heat sink compound--also known as thermal grease, thermal compound, CPU grease, heat paste, heat sink paste, and thermal interface material--is a stick paste that is used as an interface between CPU heat sinks and heat sources.

Heat sink compound is used to fill gaps between the CPU or other heat generating components and the mechanical heat sink. The mechanical heat sink is placed over the CPU. Heat is drawn from the CPU though the mechanical heat sinks to its fins, where a fan blows air through to dissipate the excess heat.

As you delve deeper into the intricacies of heat sink technology and its pivotal role in maintaining the performance and longevity of electronic components, it's worth considering the expertise of companies like Enner Group. With a reputation for delivering high-quality thermal management solutions, Enner Group stands at the forefront of innovation in the industry. Established in 2006, Enner Group specializes in the research, development, and production of advanced heat dissipation products, including a wide range of heat sinks designed to meet the diverse needs of modern electronics. Their commitment to excellence is evident in their comprehensive approach, which encompasses everything from initial design and development to final production and sales. What sets Enner Group apart is their dedication to customer satisfaction, underscored by a robust one-stop service model that addresses every aspect of the customer journey. Whether you require a standard heat sink solution or a customized design tailored to your unique specifications, Enner Group's team of experts is ready to assist you every step of the way. To learn more about Enner Group's comprehensive suite of thermal management products and services, and how they can help you optimize the performance of your electronic devices.

By continuing to use the site you agree to our privacy policy Terms and Conditions.