A Heatpipe is a sealed copper tube that is under vacuum, and can transfer heat rapidly away from the source. The High thermal conductivity enables a heat pipe to transfer, and dissipate heat to a more convenient location through a capillary action. This effect is similar to placing a paper towel in coffee, and watching the fluid rise up the paper towel. Heat pipes are available in various shapes and sizes.. The can be flat or round, and can be formed to fit most contours.

We are a leading heatpipe heatsink manufacturer with years of experience designing and producing high-quality cooling systems for electronic devices.

The use of a heatpipe for thermal management is a proven and widely applied technology. The modern concept of a capillary driven heat pipe was first i

nvented by General Motors

in 1962. NASA later adapted and further developed this concept. Heatpipes have become commonplace in some of today’s electronics systems. Computers, pipes along the Trans-Alaska Pipeline, nuclear reactors, heat-sensitive electronics aboard satellites and the International Space Station, all rely on heat pipes to manage thermal output effectively.

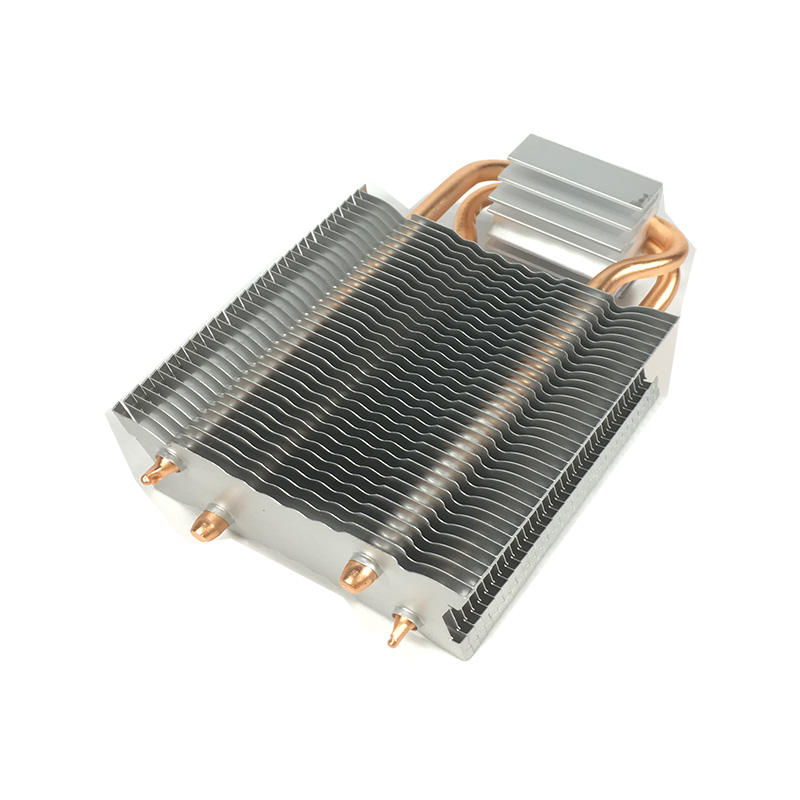

HEATPIPE CONSTRUCTION

A heatpipe heatpipe is constructed using a metal tube that is sealed under a partial vacuum. Inside the copper heatpipe is an inner wick lining that acts as a capillary material for a small amount of fluid. As heat is applied to the heatpipe surface in the evaporator region the fluid is heated and as it is under a vacuum it is easier to change it into a vapor. This phase change from a fluid to vapor creates pressure. As pressure increases the vapor will naturally flow into the cooler section of the heatpipe. Heat is then released as the vapor condenses back into a fluid. The fluid will then flow back into the warm region, where the cycle will repeat while heat is applied to the that section.

Many fluids can be used in heatpipes as the phase transition. In most applications, de-ionized water is selected as the working fluid due to its high latent heat, surface tension, thermal conductivity and boiling temperature. The negative pressure of the vacuum within heat pipes allows the water to boil and turn into steam at lower temperatures than normal. The internal wick can vary depending upon the application and orientation of the cooling device. The three most common methods are:

By continuing to use the site you agree to our privacy policy Terms and Conditions.