News

Site Editor

Site

/uploads/image/658e1b5398ef3.png

Site

/uploads/image/658e1b5398ef3.png

Understanding Heat Sinks: The Unsung Heroes of Thermal Management

Views: 1806

Author: Site Editor

Publish Time: 2024-05-27

Origin: Site

In the world of electronics and high-performance computing, managing heat is a critical concern. As devices become more powerful and compact, the amount of heat generated by components such as CPUs, GPUs, and power transistors increases. If not properly managed, this heat can lead to reduced performance, component failure, and shortened lifespan of electronic devices. This is where heat sinks come into play. Heat sinks are essential components that help dissipate heat away from critical parts, ensuring optimal performance and longevity of electronic devices. This article provides an in-depth look at what heat sinks are, how they work, and their various applications.

What Are Heat Sinks?

A heat sink is a passive heat exchanger that transfers heat generated by an electronic or mechanical device to a fluid medium, often air or liquid coolant, where it is dissipated away from the device, thereby regulating its temperature. The primary function of a heat sink is to increase the surface area available for heat dissipation, facilitating the transfer of heat from a hot component to the cooler medium.

How Do Heat Sinks Work?

The working principle of a heat sink involves three main mechanisms: conduction, convection, and radiation.

-

Conduction:

-

Heat is transferred from the hot component to the heat sink through direct contact. The efficiency of this process depends on the thermal conductivity of the materials used. Metals such as aluminum and copper, which have high thermal conductivity, are commonly used in heat sinks.

-

Convection:

-

Once the heat is transferred to the heat sink, it is dissipated to the surrounding fluid (usually air) through convection. In natural convection, the heat sink relies on the natural circulation of air to remove heat. In forced convection, fans or blowers are used to enhance airflow over the heat sink, improving its cooling efficiency.

-

Radiation:

-

A smaller portion of heat is dissipated through thermal radiation, where heat is emitted from the heat sink surface in the form of infrared radiation. This process is less significant compared to conduction and convection but still contributes to overall heat dissipation.

Types of Heat Sinks

There are various types of heat sinks, each designed for specific applications and thermal requirements. Some common types include:

-

Passive Heat

Sinks:

-

These rely solely on natural convection to dissipate heat. They are typically made from extruded aluminum and have fins or pins to increase surface area. Passive heat sinks are quiet and reliable but may not provide sufficient cooling for high-power components.

-

Active

Heat

Sinks:

-

These incorporate fans or blowers to enhance heat dissipation through forced convection. Active heat sinks are more effective than passive ones in cooling high-power devices but can introduce noise and require additional power.

-

Liquid-Cooled Heat Sinks:

-

These use liquid coolant to transfer heat away from the component. The liquid is circulated through a closed loop, where it absorbs heat from the heat sink and releases it through a radiator. Liquid-cooled systems are highly efficient and are often used in high-performance computing and gaming applications.

-

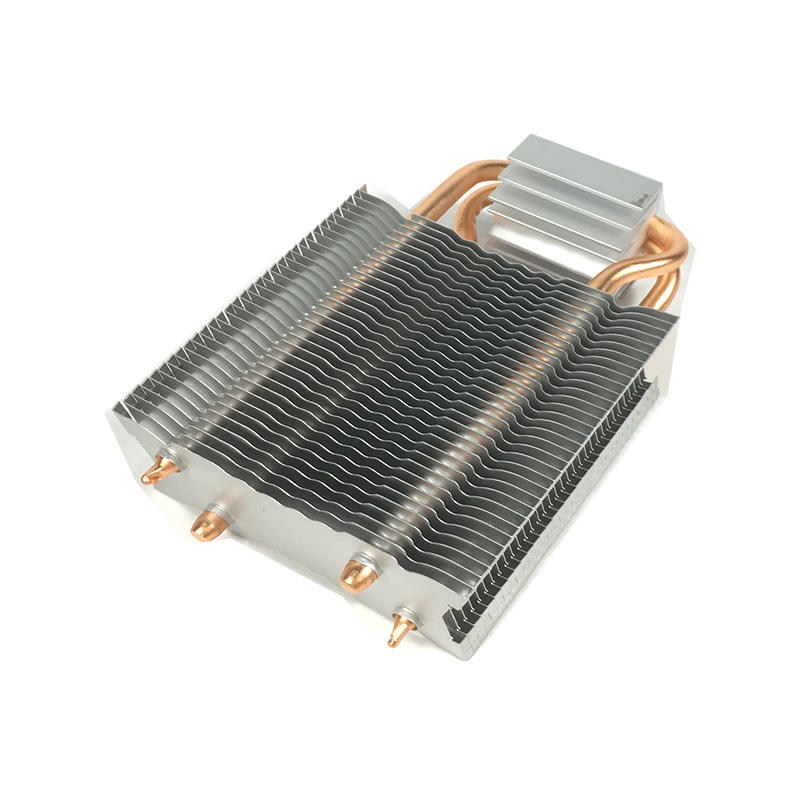

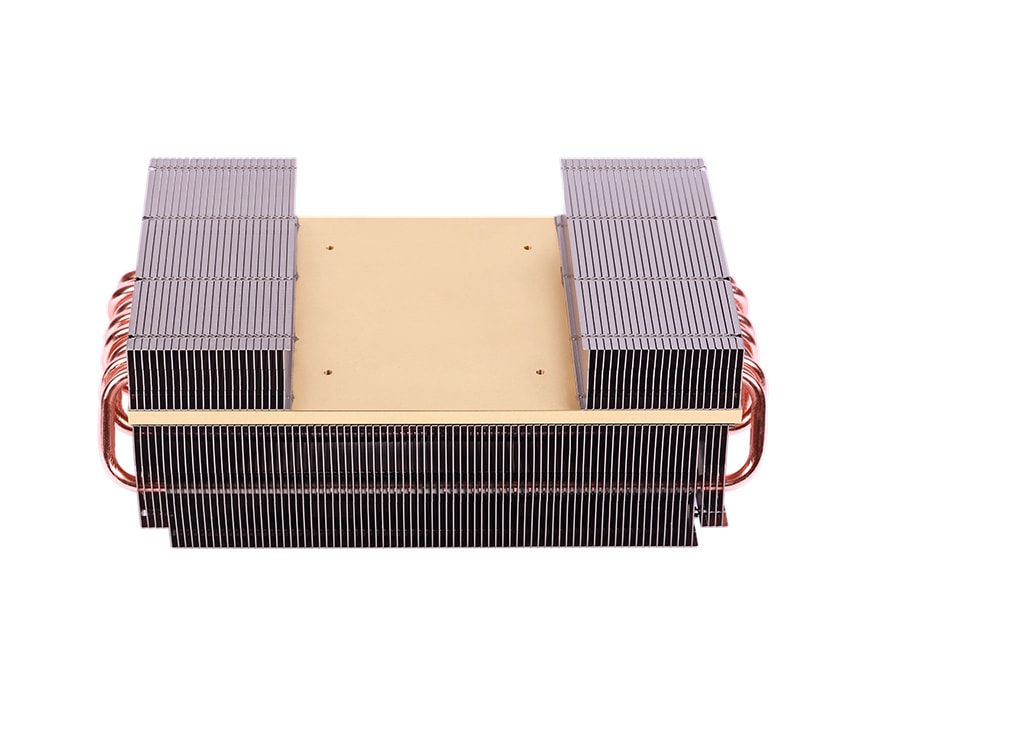

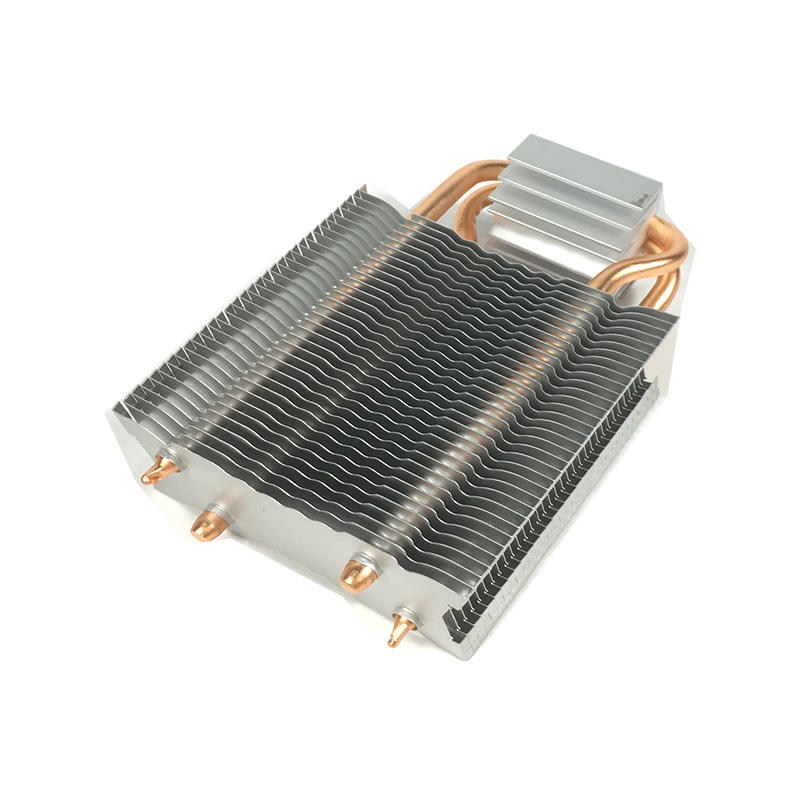

Heat Pipe Heat Sinks:

-

These combine the principles of both passive and active cooling. Heat pipes are sealed tubes filled with a working fluid that evaporates and condenses to transfer heat. They are often integrated into heat sinks to improve thermal performance without the need for active cooling.

-

Vapor Chamber Heat Sinks:

-

Similar to heat pipes, vapor chambers are flat, sealed chambers that use the phase change of a working fluid to spread heat evenly across the heat sink. They are effective in applications where uniform heat distribution is critical.

Applications of Heat Sinks

Heat sinks are used in a wide range of applications across various industries. Some notable applications include:

-

Computers and Electronics:

-

In personal computers, heat sinks are used to cool CPUs, GPUs, chipsets, and power supply units. They ensure these components operate within safe temperature limits, enhancing performance and reliability.

-

LED Lighting:

-

High-power LEDs generate significant heat, which can reduce their lifespan and efficiency. Heat sinks help dissipate this heat, maintaining the performance and longevity of LED lighting systems.

-

Telecommunications:

-

In telecommunications equipment, heat sinks are used to cool power amplifiers, transceivers, and other critical components, ensuring stable operation and preventing thermal shutdowns.

-

Automotive:

-

Modern vehicles rely on electronic control units (ECUs) and other electronic systems that generate heat. Heat sinks help manage this heat, preventing thermal damage and ensuring reliable vehicle operation.

-

Renewable Energy:

-

In renewable energy systems, such as solar inverters and wind turbines, heat sinks are used to cool power electronics, improving efficiency and extending the lifespan of the systems.

-

Industrial Machinery:

-

Heat sinks are used in various industrial applications, from motor controllers to power supplies, to maintain optimal operating temperatures and prevent overheating.

Factors to Consider When Choosing a Heat Sink

Selecting the appropriate heat sink involves several considerations:

-

Thermal Resistance:

-

The thermal resistance of a heat sink indicates its ability to dissipate heat. Lower thermal resistance means better heat dissipation. This parameter depends on the material, design, and surface area of the heat sink.

-

Material:

-

The material of the heat sink affects its thermal conductivity. Copper has higher thermal conductivity than aluminum but is heavier and more expensive. Aluminum is lightweight and cost-effective but less efficient in conducting heat.

-

Size and Shape:

-

The size and shape of the heat sink should match the thermal requirements of the component and the available space. Larger heat sinks with more surface area can dissipate more heat but may not fit in compact spaces.

-

Airflow:

-

Adequate airflow is essential for effective heat dissipation. The placement of the heat sink and the surrounding environment should facilitate proper airflow, whether through natural or forced convection.

-

Mounting Method:

-

The method of attaching the heat sink to the component is crucial for efficient heat transfer. Thermal interface materials (TIMs) such as thermal paste, pads, or adhesives are used to improve contact and reduce thermal resistance.

Heat sinks are vital components in the thermal management of electronic and mechanical devices. By efficiently dissipating heat, they ensure optimal performance, reliability, and longevity of components. Understanding the various types of heat sinks and their applications allows for informed decisions in designing and maintaining systems that generate heat. As technology continues to advance, the role of heat sinks in managing thermal challenges will remain crucial, driving innovation and enhancing the capabilities of electronic devices across industries.