In the first part of this series, we explored the types of heat dissipation materials used in thermal management. Now, let’s dive into the components that leverage these materials to effectively dissipate heat and ensure the reliable operation of electronic devices. From heat sinks to vapor chambers, these components play a critical role in maintaining optimal temperatures for high-performance electronics.

Heat dissipation components are designed to maximize the surface area available for heat transfer and enhance the thermal conductivity of materials. Below are some of the most commonly used components:

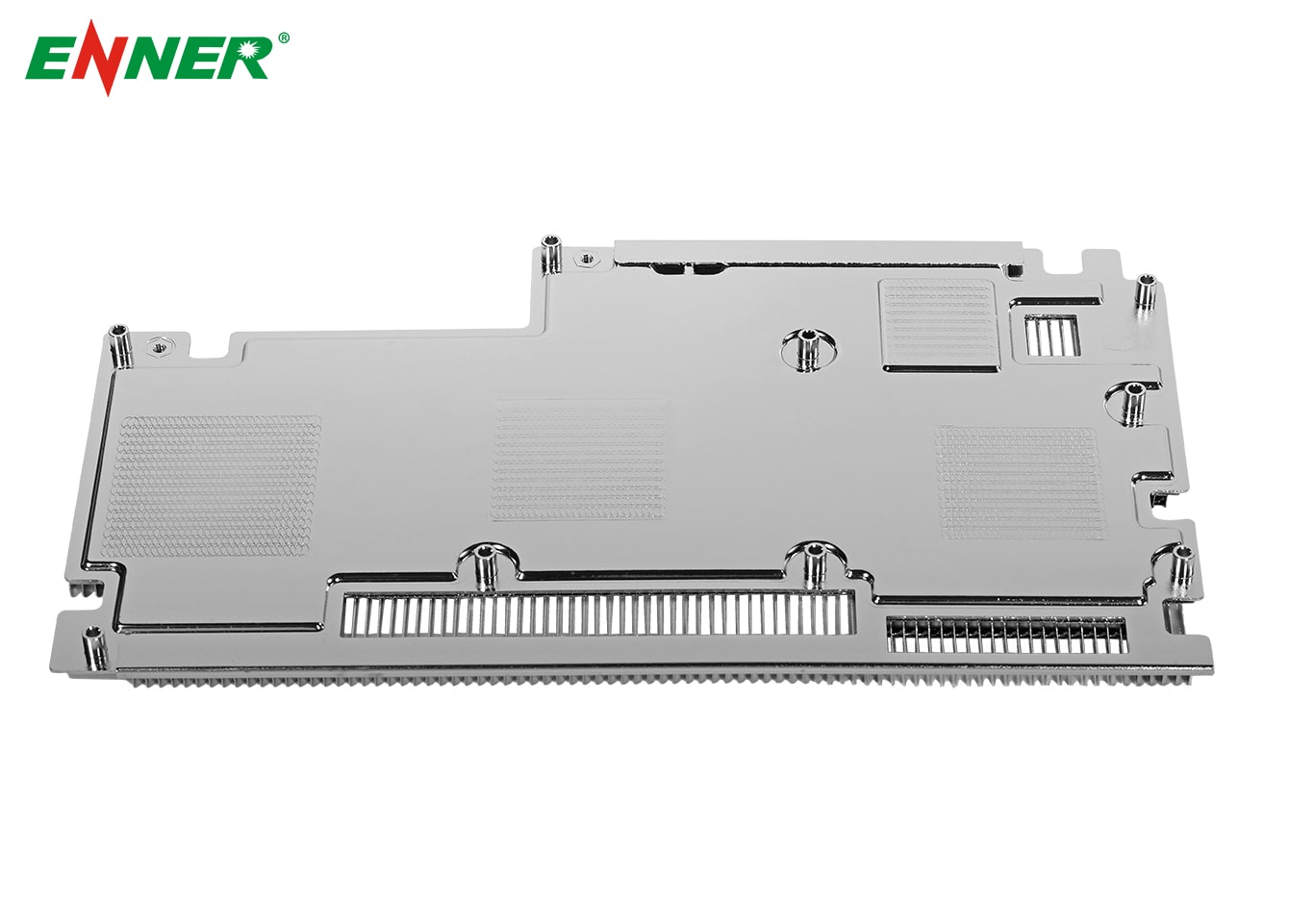

Heat sinks are one of the most common components used to dissipate heat. They feature a flat surface in contact with the heat source, and fins or rods on the opposite side to increase the surface area for heat transfer.

Graphite sheets are thin, flexible materials with high thermal conductivity along the plane of the layers. These sheets are often used in applications where space is limited.

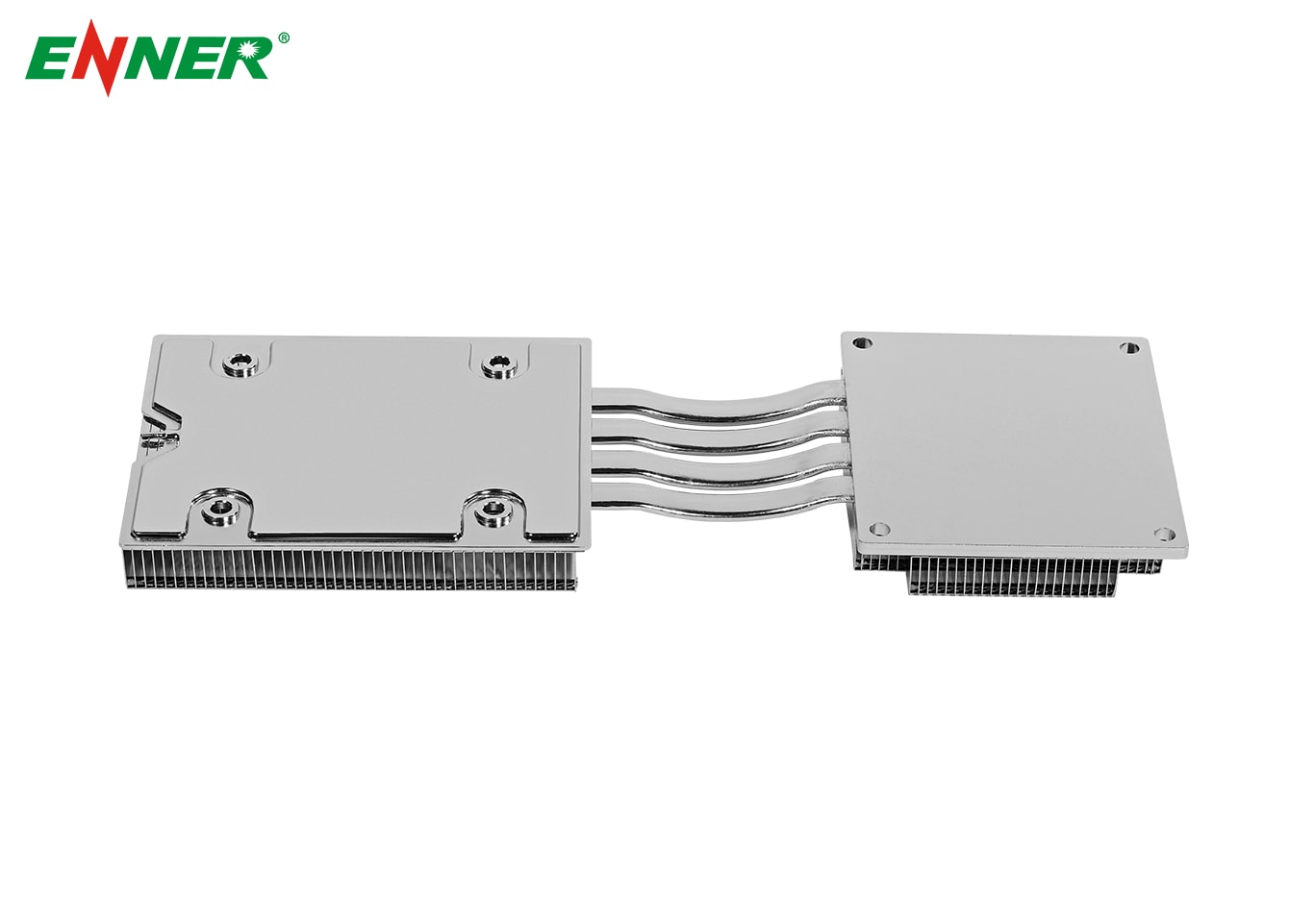

Heat pipes are sealed metal tubes (often made of copper) filled with a working fluid that helps transfer heat away from a component. When the fluid inside the heat pipe is heated by a source, it vaporizes and moves to a cooler part of the pipe, where it condenses and releases the heat.

Vapor chambers are similar to heat pipes but are typically flat and belt-shaped rather than cylindrical. They have multiple grooves and wicks that allow a working fluid to move through the chamber efficiently, much like in heat pipes.

TIMs are used to improve the thermal connection between heat dissipation components (such as heat sinks or heat pipes) and the heat source, typically an electronic component.

Effective thermal management relies not only on the right materials but also on the components that utilize them. From heat sinks and graphite sheets to advanced heat pipes and vapor chambers, each component offers unique advantages for specific applications. By understanding these options, you can design systems that ensure optimal performance and longevity for your electronic devices.

At Enner , we specialize in providing high-performance heat dissipation solutions tailored to your needs. If you're looking for reliable thermal management for your electronic devices or components, contact us today to learn how we can assist with your custom needs.

By continuing to use the site you agree to our privacy policy Terms and Conditions.