Effective heat dissipation is essential for the reliable operation of electronic devices, especially those that generate significant heat, such as System on Chips (SoCs) and high-density circuit boards. If not properly managed, excessive heat can lead to malfunctions, reduced performance, and shortened lifespans of electronic components. To prevent these issues, various heat dissipation materials are used to transfer heat away from sensitive parts of electronic devices. In this article, we’ll explore the types of heat dissipation materials, their characteristics, and how they work to improve thermal management.

The most common materials used for heat dissipation are metals, ceramics, and graphite. Each material has its own advantages and disadvantages, making them suitable for different applications.

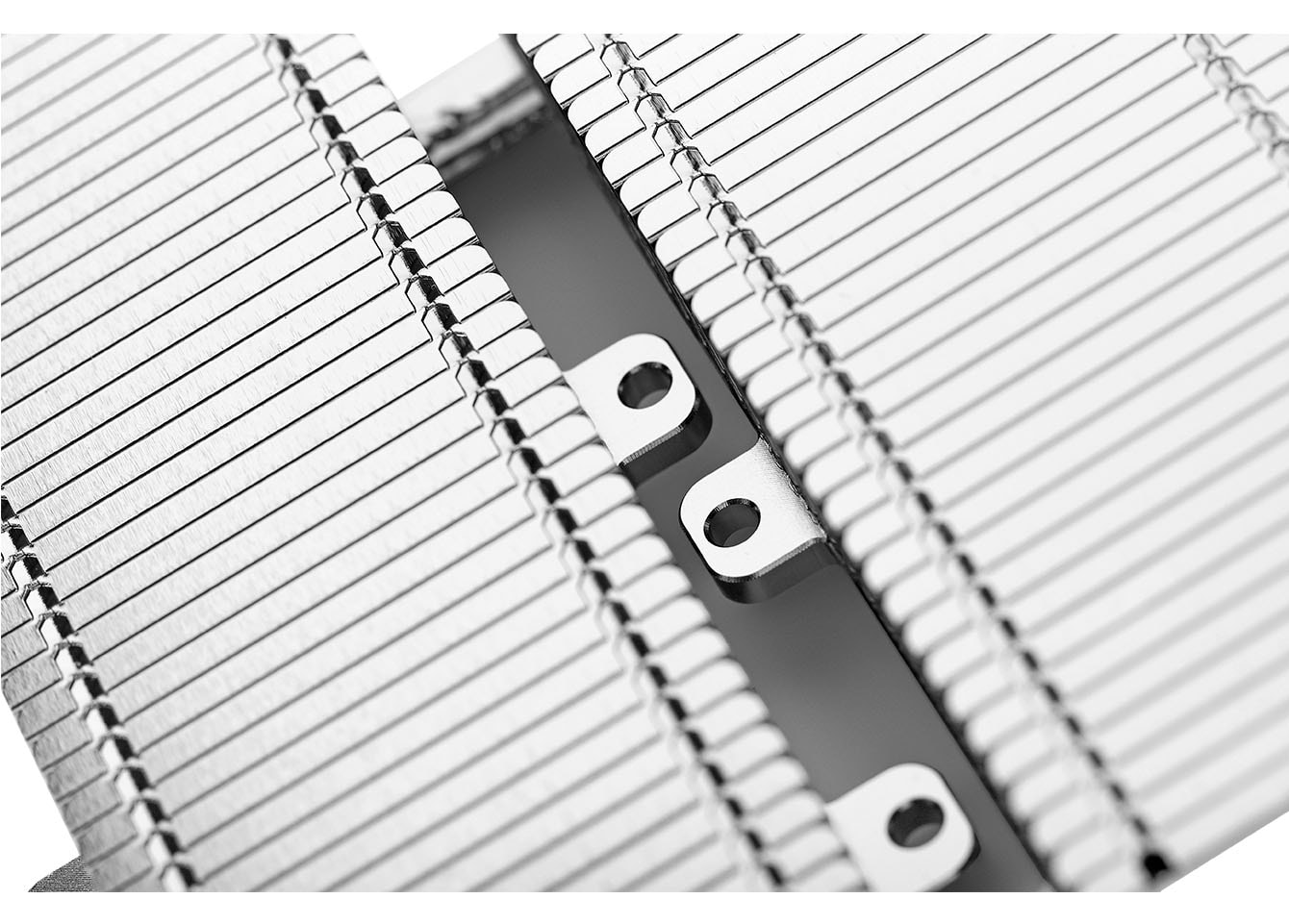

Metals are often the go-to choice for heat dissipation components like heat sinks and heat spreaders due to their high thermal conductivity.

Ceramics, like aluminum nitride, are used in some heat dissipation components, especially where electrical insulation is needed.

When choosing heat dissipation materials, several factors must be considered to ensure optimal performance and cost-effectiveness:

While copper offers superior thermal conductivity, its higher cost may not be justified for all applications. Aluminum, with its lower cost and lighter weight, is often a more practical choice for consumer electronics.

In applications like aerospace and mobile devices, weight and space are critical. Graphite and aluminum are preferred for their lightweight properties, while ceramics may be used in compact designs requiring electrical insulation.

Materials must withstand the operating environment. For example, aluminum’s rust resistance makes it suitable for humid conditions, while ceramics excel in high-temperature or corrosive environments.

In electronic devices, materials like copper and graphite require careful insulation to prevent short circuits, whereas ceramics provide natural electrical isolation.

Graphite’s flexibility allows it to fit into tight spaces, while metals like aluminum are easier to machine into complex shapes. Ceramics, though brittle, can be precision-molded for specialized applications.

Understanding the properties of heat dissipation materials and the factors influencing their selection is crucial for effective thermal management. Whether you need the high conductivity of metals, the electrical insulation of ceramics, or the flexibility of graphite, choosing the right material can significantly enhance the performance and longevity of your electronic devices.

At Enner , we specialize in providing high-performance heat dissipation solutions tailored to your needs. If you're looking for reliable thermal management for your electronic devices or components, contact us today to learn how we can assist with your custom needs.

By continuing to use the site you agree to our privacy policy Terms and Conditions.