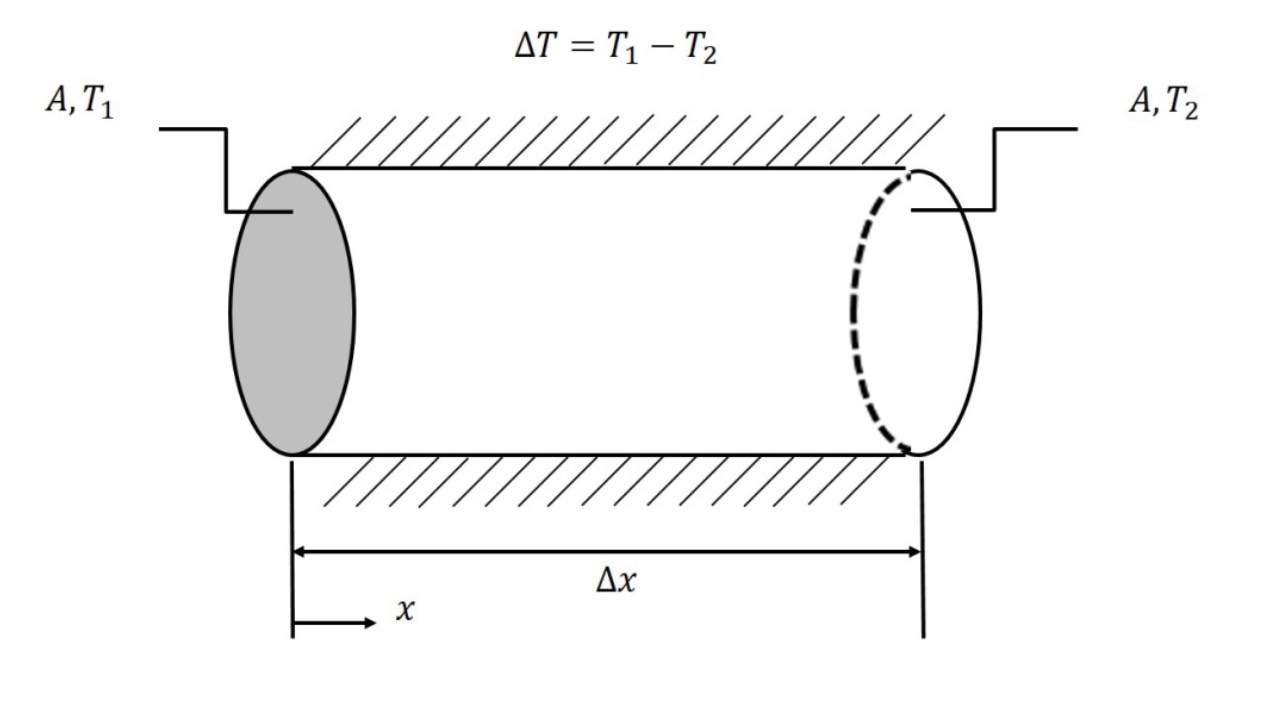

Thermal resistance is a measure of a material’s ability to resist the flow of heat. In the context of heat sinks, it quantifies the heat sink's efficiency in transferring heat away from the heat-generating component to the surrounding environment. Thermal resistance is typically expressed in degrees Celsius per watt (°C/W). Lower thermal resistance indicates a more efficient heat sink, as it can dissipate more heat for a given temperature difference.

1. Enhanced Performance: Electronic components, especially high-performance ones like CPUs and GPUs, generate significant heat. Low thermal resistance ensures that this heat is efficiently dissipated, maintaining optimal operating temperatures and preventing thermal throttling, which can degrade performance.

2. Longevity of Components: High operating temperatures can accelerate the degradation of electronic components. Effective thermal management through low thermal resistance helps in prolonging the lifespan of these components by keeping temperatures within safe limits.

3. System Reliability: Maintaining lower temperatures reduces the risk of thermal-induced failures. This is particularly critical in industries such as aerospace, automotive, and medical devices where reliability is paramount.

1. Material: The thermal conductivity of the material used in a heat sink significantly affects its thermal resistance. Materials with high thermal conductivity, such as copper and aluminum, are preferred for heat sinks due to their superior ability to conduct heat.

2. Design and Surface Area: The design of the heat sink, including the fin geometry and surface area, plays a crucial role. A larger surface area with more fins increases the heat dissipation capability, thereby reducing thermal resistance.

3. Airflow: The efficiency of heat dissipation also depends on the airflow around the heat sink. Improved airflow reduces the boundary layer of stagnant air that can act as an insulating layer, thereby lowering thermal resistance.

4. Contact Resistance: The thermal resistance at the interface between the heat sink and the heat-generating component can significantly impact overall thermal performance. Using thermal interface materials (TIMs) such as thermal paste can help minimize this resistance.

Optimizing Thermal Resistance in Heat Sinks

1. Selecting the Right Material: Choose heat sinks made from materials with high thermal conductivity. Copper and aluminum are commonly used due to their excellent heat dissipation properties.

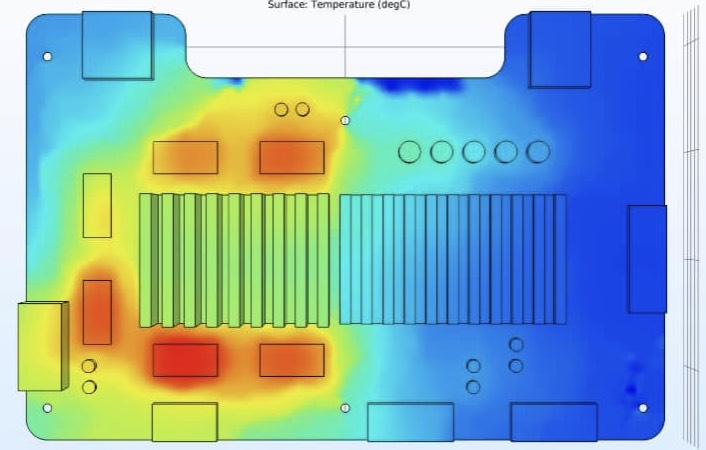

2. Optimized Design: Use advanced simulation tools to design heat sinks with optimal fin geometries and surface areas that maximize heat dissipation. Considerations like fin thickness, spacing, and overall dimensions are crucial.

3. Enhancing Airflow: Ensure adequate ventilation in the system design. Using fans or natural convection methods can significantly improve airflow, reducing thermal resistance. Positioning and orientation of the heat sink to take advantage of airflow patterns can also make a difference.

4. Quality Thermal Interface Materials: Apply high-quality thermal paste or pads between the heat sink and the component to reduce contact resistance. Ensure that the application is even and covers the entire contact area to maximize heat transfer.

5. Regular Maintenance: Over time, dust and debris can accumulate on heat sinks, reducing their efficiency. Regular cleaning and maintenance are essential to keep the heat sinks functioning at their best.

Advanced Techniques

1. Vapor Chamber Heat Sinks: Incorporating vapor chambers in heat sinks can further enhance heat dissipation. Vapor chambers spread the heat more evenly across the heat sink, reducing hot spots and improving overall efficiency.

2. Heat Pipes: Using heat pipes in conjunction with heat sinks can also improve thermal management. Heat pipes can transfer heat from the component to a larger heat sink area more efficiently, thereby reducing thermal resistance.

3. Active Cooling Solutions: In cases where passive cooling is insufficient, active cooling solutions such as liquid cooling or thermoelectric coolers can be employed. These systems actively transport heat away from the components, significantly reducing thermal resistance.

Effective thermal management is crucial for the performance, reliability, and longevity of electronic components. Understanding and optimizing heat sink thermal resistance is a key aspect of this process. By selecting the right materials, designing efficient heat sinks, enhancing airflow, and using quality thermal interface materials, you can significantly improve the thermal performance of your systems. As technology advances, incorporating advanced cooling techniques like vapor chambers and heat pipes will continue to push the boundaries of thermal management, ensuring that electronic devices can operate at peak performance even under the most demanding conditions.

By continuing to use the site you agree to our privacy policy Terms and Conditions.