In the realm of electronics, thermal management is a critical concern, directly influencing the performance and longevity of devices. Heat sinks are indispensable in this regard, as they facilitate the dissipation of heat generated by electronic components. Among the various methods of heat sink fabrication, welding stands out for its ability to create robust and efficient thermal management solutions. This article delves into the advantages, processes, and applications of welding heat sinks, highlighting their importance in modern electronics.

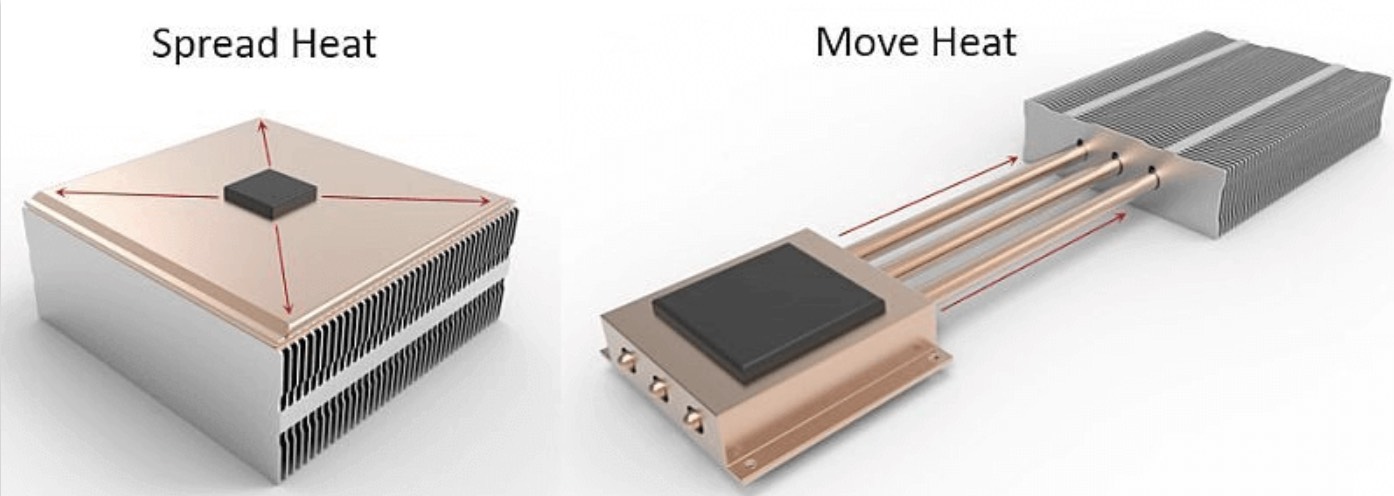

Heat sinks are designed to increase the surface area for heat dissipation, thereby lowering the temperature of electronic components. Effective heat sinks ensure that components operate within safe temperature limits, preventing overheating and thermal throttling. This is especially crucial in high-performance and high-density electronics, where efficient thermal management can significantly impact overall system performance.

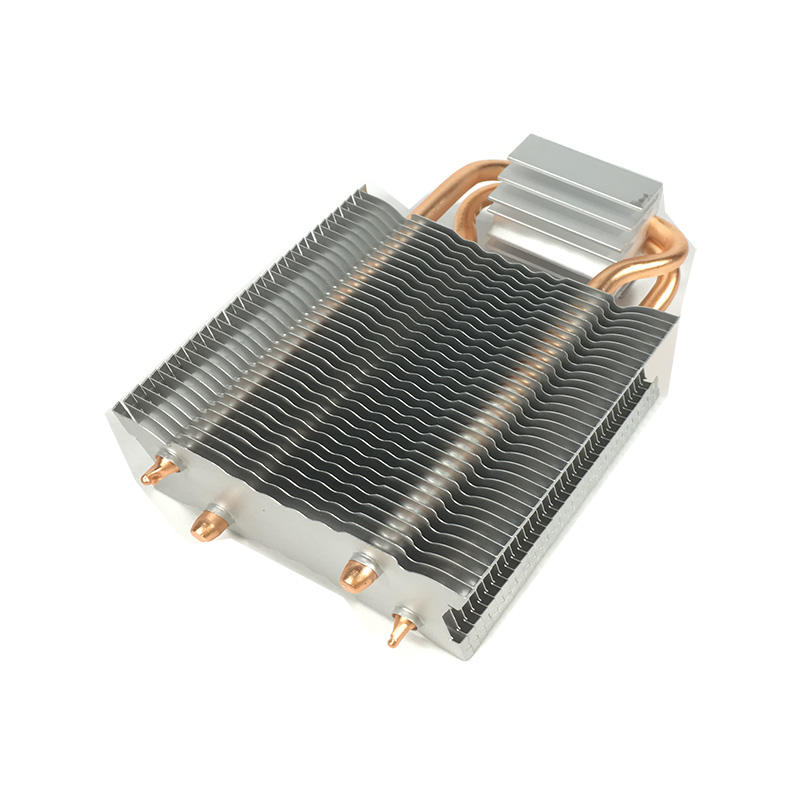

A welding heat sink refers to a heat sink fabricated through welding processes. Welding involves joining two or more pieces of metal by melting their edges and allowing them to cool, forming a strong, permanent bond. This method is particularly advantageous for creating complex heat sink structures with high thermal conductivity and mechanical strength.

Strong Bonding: Welding creates a robust bond between metal parts, ensuring the structural integrity of the heat sink. This is essential for heat sinks used in high-stress environments or applications with significant mechanical vibrations.

High Thermal Conductivity: Welding allows the use of materials with high thermal conductivity, such as aluminum and copper. The strong bond formed through welding ensures efficient heat transfer between the heat sink components.

Flexibility in Design: Welding provides flexibility in designing heat sinks with complex geometries and shapes. This is particularly beneficial for applications requiring custom solutions to fit specific spatial constraints or performance requirements.

Durability: Welded heat sinks are highly durable and can withstand harsh environmental conditions, making them suitable for use in demanding applications such as aerospace, automotive, and industrial machinery.

Several welding techniques can be employed to fabricate heat sinks, each with its own set of advantages and applications:

TIG Welding (Tungsten Inert Gas): TIG welding is known for its precision and control, making it ideal for welding thin materials and creating intricate heat sink designs. It produces high-quality welds with minimal contamination.

MIG Welding (Metal Inert Gas): MIG welding is faster and more cost-effective than TIG welding, making it suitable for large-scale production. It provides good weld penetration and is suitable for thicker materials.

Laser Welding: Laser welding uses a focused laser beam to join materials, offering high precision and minimal heat-affected zones. It is ideal for creating small, detailed heat sink components with high accuracy.

Ultrasonic Welding: This technique uses high-frequency ultrasonic vibrations to weld materials together. It is commonly used for joining dissimilar materials and is ideal for applications where traditional welding methods are impractical.

Welding heat sinks are used in a wide range of applications, each benefiting from the unique advantages of welded construction:

Aerospace: In aerospace applications, where weight and reliability are critical, welded heat sinks provide efficient thermal management for avionics, power electronics, and communication systems. Their durability ensures performance in extreme conditions.

Automotive: Modern vehicles rely heavily on electronics for various functions, from engine control units to infotainment systems. Welded heat sinks help manage the heat generated by these components, ensuring optimal performance and longevity.

Industrial Machinery: Heavy machinery and industrial equipment generate substantial amounts of heat. Welded heat sinks are used to dissipate this heat, maintaining operational efficiency and preventing overheating.

Consumer Electronics: High-performance consumer electronics, such as gaming consoles and computers, require effective thermal management to operate efficiently. Welded heat sinks provide the necessary heat dissipation to keep these devices cool.

Renewable Energy Systems: Solar inverters, wind turbine controllers, and other renewable energy systems generate significant heat. Welded heat sinks are employed to manage this heat, ensuring the reliability and efficiency of these systems.

To maximize the performance of welded heat sinks, several factors need to be considered:

Material Selection: Choose materials with high thermal conductivity, such as copper or aluminum, to ensure efficient heat transfer. The choice of material also depends on the specific requirements of the application, such as weight, cost, and environmental resistance.

Design Considerations: Design the heat sink to maximize surface area while minimizing airflow resistance. Incorporate fins, channels, and other features to enhance heat dissipation. The design should also consider the thermal interface with the electronic component.

Quality Control: Implement stringent quality control measures during the welding process to ensure the integrity and consistency of the welds. Regular inspection and testing can help identify and rectify defects early.

Thermal Interface Materials: Use high-quality thermal interface materials (TIMs) between the heat sink and the component to reduce thermal resistance and improve heat transfer. Proper application of TIMs is crucial for optimal performance.

As electronic devices continue to evolve, the demand for more efficient and compact heat sinks will grow. Innovations in welding technology and materials science will drive the development of advanced heat sinks with improved thermal performance and reliability. Key trends to watch include:

Advanced Materials: The use of advanced materials, such as graphene and phase-change materials, in conjunction with welding techniques will enhance the thermal conductivity and performance of heat sinks.

Additive Manufacturing: Combining welding with additive manufacturing (3D printing) will enable the creation of complex, custom heat sink designs that are difficult to achieve with traditional methods.

Integrated Cooling Solutions: The development of integrated cooling solutions, where heat sinks are built directly into electronic components, will improve thermal management and reduce overall system size and weight.

Welding heat sinks offer a robust and efficient solution for thermal management in a variety of applications. Their strong bonding, high thermal conductivity, and design flexibility make them ideal for use in demanding environments. By optimizing material selection, design, and quality control, welded heat sinks can significantly enhance the performance and reliability of electronic devices. As technology advances, the future of welding heat sinks promises even greater innovations, ensuring that electronic components can operate efficiently and reliably in increasingly challenging conditions.

By continuing to use the site you agree to our privacy policy Terms and Conditions.