Liquid cooling is an advanced heat dissipation method that uses liquid as a medium to transfer heat away from electronic components or mechanical systems. Compared to traditional air cooling, liquid cooling can more efficiently remove heat, making it a preferred solution in high-performance computing, data centers, electric vehicles, and industrial equipment. Liquid cooling can generally be divided into direct cooling and indirect cooling , with immersion cooling and cold plate cooling as the main technologies under these categories.

Immersion cooling involves submerging heat-generating components directly into a cooling liquid, where the liquid circulates to carry away the heat produced by devices like servers. This is a typical direct contact liquid cooling method. Since the heat source is in direct contact with the cooling liquid, this system offers higher thermal efficiency and reduced noise. Immersion cooling systems are typically divided into two cycles: the indoor and outdoor cycles.

In the indoor cycle, the cooling liquid exchanges heat with the heat-generating components within a sealed chamber. As the liquid absorbs the heat, it warms up and vaporizes. The vaporized liquid then moves to a heat exchange module (CDM), where it condenses as it exchanges heat with the cooler outdoor-side water. The condensed liquid is cooled down and recirculated into the chamber to repeat the process. In two-phase immersion cooling systems, the liquid undergoes a phase change to efficiently transfer heat.

In the outdoor cycle, the now high-temperature water that absorbed the heat from the cooling liquid is pumped to an external cooling tower. In the cooling tower, the water releases heat to the atmosphere, returning to a lower temperature before being pumped back into the CDM for another round of heat exchange. In this cycle, heat transfer is primarily achieved through changes in the water temperature.

Immersion cooling systems can be divided into two-phase and single-phase systems, each with unique characteristics.

Two-Phase Liquid Cooling : In two-phase systems, the cooling liquid changes from liquid to vapor and back during the cooling process. This method is highly efficient but also more complex to manage. The pressure changes during phase transitions, requiring durable containers, and the liquid is more susceptible to contamination.

Single-Phase Liquid Cooling : In single-phase systems, the liquid remains in the same state throughout the cooling process. The liquid has a high boiling point to prevent evaporation losses, making it easier to control, but the cooling efficiency is generally lower than two-phase systems.

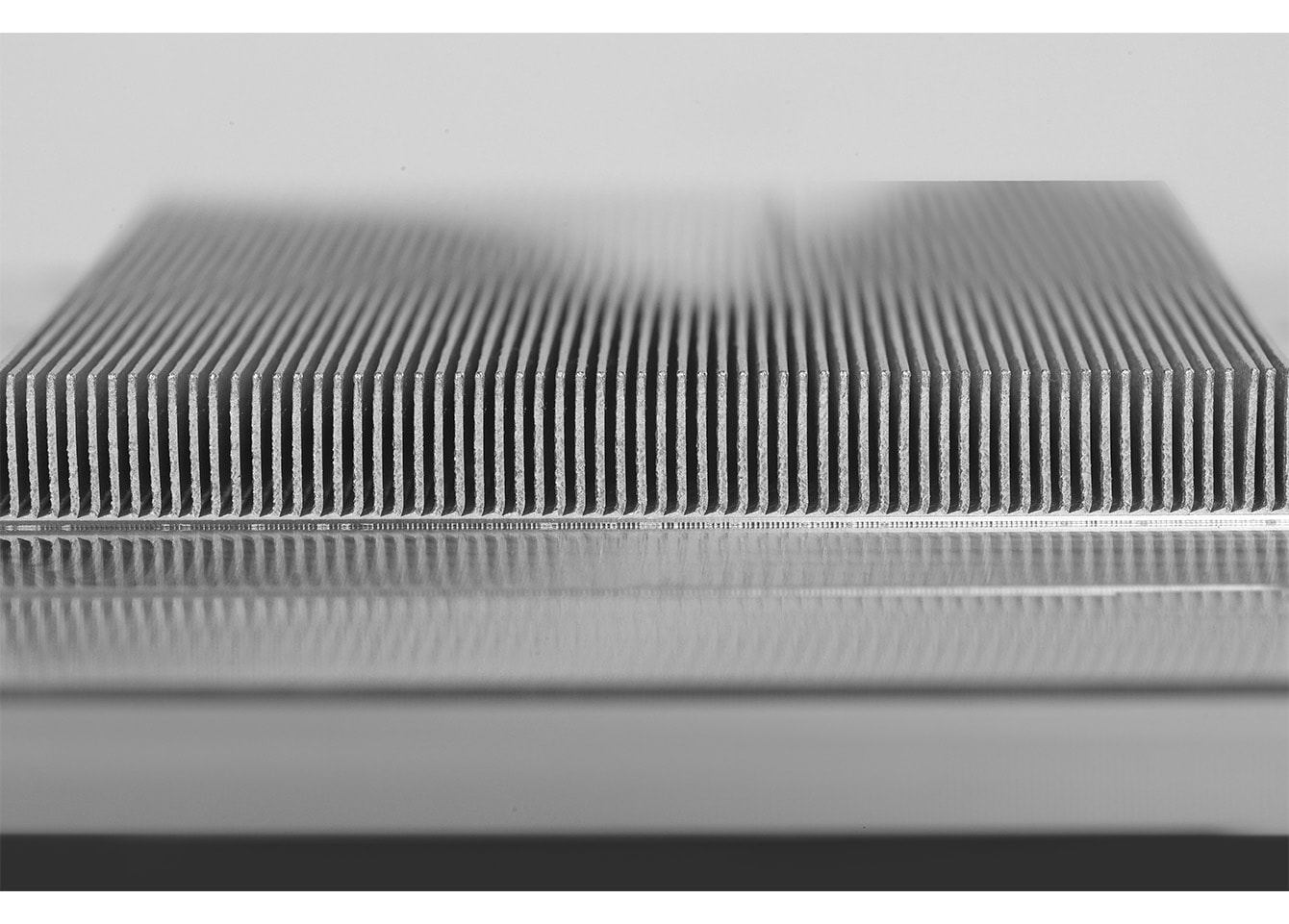

Cold plate cooling involves attaching liquid cooling plates to the main heat-generating components of a server. The liquid circulates through the plates, absorbing heat from these components and dissipating it. While cold plate cooling effectively handles high-heat components, other parts of the server may still require air cooling, leading to hybrid systems known as dual-channel servers . The liquid in cold plate systems does not directly contact the components but transfers heat through a thermal plate, offering high safety and reliability.

Spray cooling systems store coolant in the top of a chassis, and then spray the coolant directly onto the heat-generating components. The liquid directly contacts the components, providing efficient cooling. However, as the liquid hits hot surfaces, some of it evaporates, which can lead to vapor escaping through gaps in the chassis, potentially affecting the cleanliness of the environment or other equipment.

Several types of coolants are used in liquid cooling systems, each with its own properties and applications:

Water : The most basic and cost-effective coolant. While water has high thermal conductivity, it is not an insulator and can cause serious damage if leakage occurs.

Mineral Oil : A non-toxic, non-volatile liquid often used in single-phase cooling systems. It has high viscosity, which can leave residues, and although it has a high flash point, it can still pose a fire risk under certain conditions.

Fluorinated Electronic Liquid : Known for being non-conductive and non-flammable, this liquid is widely used in data centers. It is highly effective but expensive.

BO Series Thermal Fluid : This specialized fluid is non-toxic, non-conductive, high boiling point, and corrosion-resistant. It prevents oxidation and contamination, which helps extend the lifespan of electronic components.

Liquid cooling, with its superior thermal management capabilities and quieter operation, is emerging as the preferred solution for high-performance electronics, particularly in data centers, electric vehicles, and industrial settings. Though the cost and complexity are higher, the long-term benefits of improved cooling efficiency and system reliability make it a worthwhile investment.

At ENNER , we offer a wide range of thermal management solutions, including heatpipe cooling systems , vapor chamber heatsinks , CNC machining parts and accessories, ensuring your equipment performs at its best even under high heat conditions.

By continuing to use the site you agree to our privacy policy Terms and Conditions.