Printed circuit boards (PCBs) are the foundation of modern electronic devices, responsible for connecting and powering components efficiently. However, as devices become more compact and power-intensive, the challenge of managing heat dissipation grows significantly. Without proper heat management, high temperatures can lead to malfunctions, reduced lifespan, or even catastrophic failure.

This article explores the importance of heat dissipation, highlights effective techniques, and explains how heat sinks enhance thermal management in PCBs.

PCBs generate heat as current flows through their components. The amount of heat depends on factors such as power density, circuit design, and operating conditions. Without proper dissipation, this heat can cause:

Component Damage : Excess heat can oxidize materials or disrupt circuit pathways.

Reduced Reliability : Thermal stress affects the structural integrity of the board.

Performance Degradation : Overheating can impair electronic components like processors and regulators.

These risks underscore the need for efficient thermal management strategies to ensure consistent performance and device longevity.

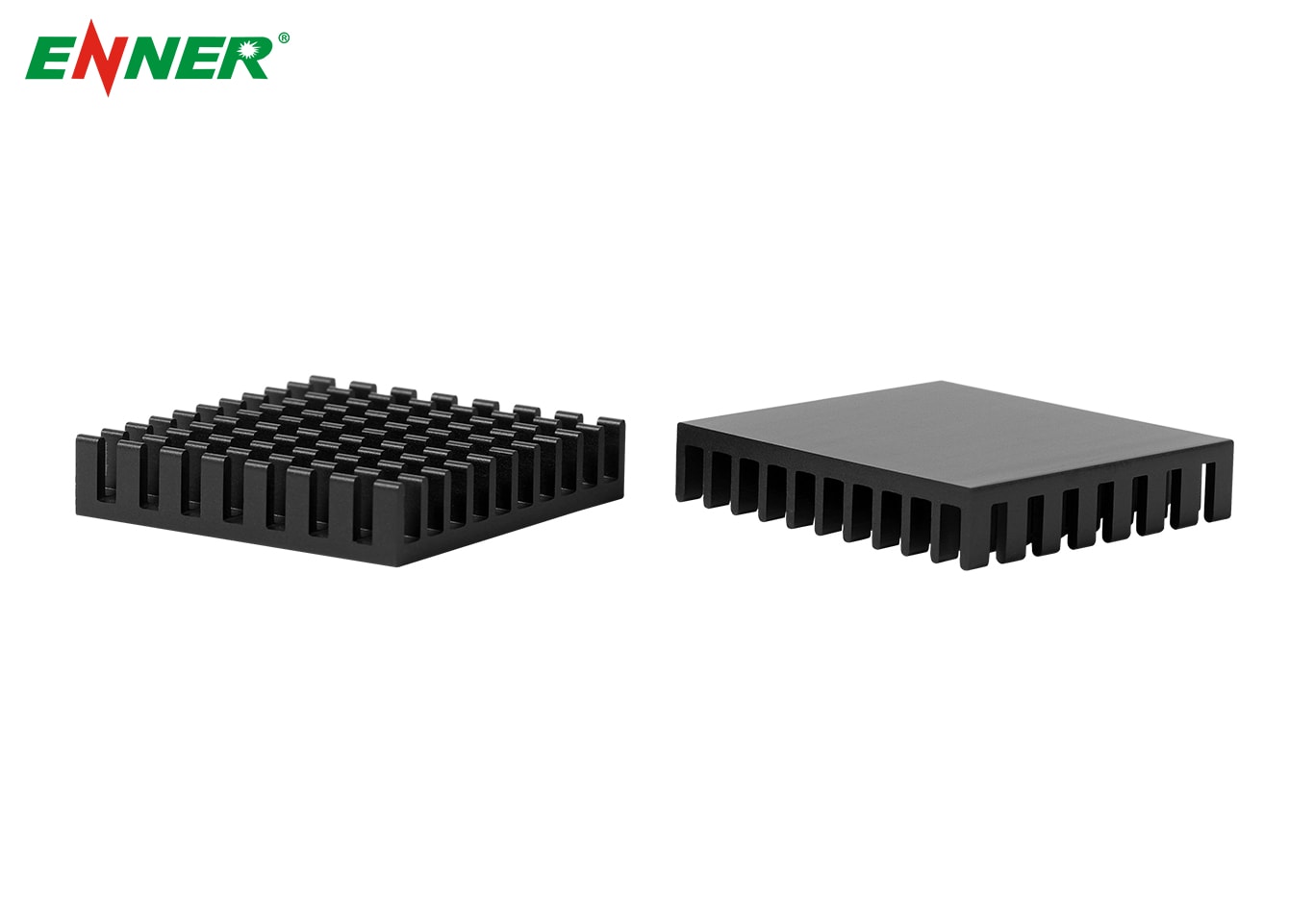

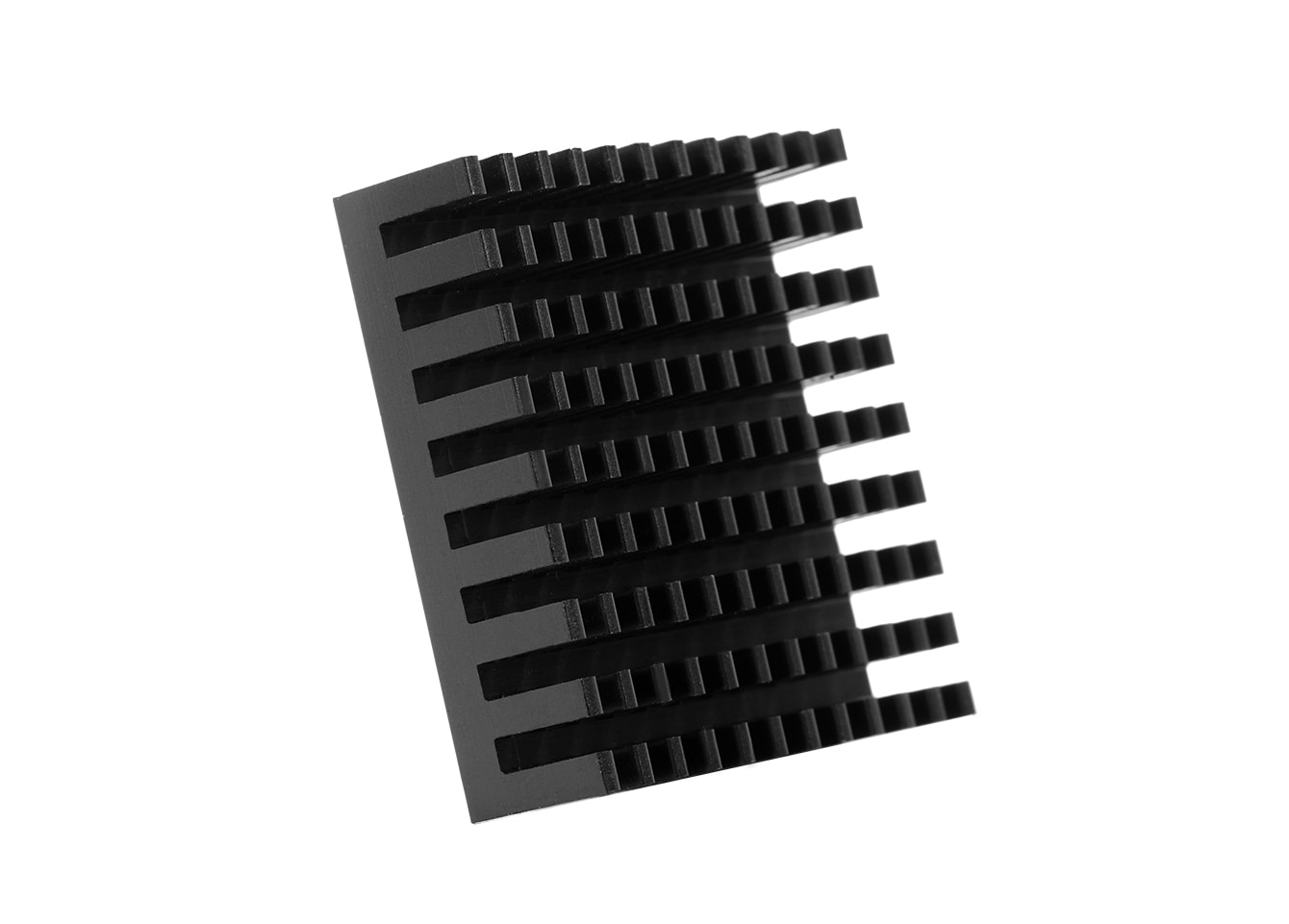

A heat sink is a thermally conductive component attached to heat-producing parts of a PCB to draw and disperse heat. Heat sinks are usually made of materials like aluminum or copper, known for their high thermal conductivity.

How It Works : Heat sinks transfer heat away from components, spreading it over a larger surface area to cool efficiently through convection.

Types of Heat Sinks :

Passive Heat Sinks : Rely on natural convection and are ideal for low-power applications.

Active Heat Sinks : Combine heat sinks with fans for forced convection, suitable for high-power devices.

Adding cooling fans alongside heat sinks enhances airflow, rapidly removing heat from components. This combination is commonly used in power supplies and high-performance computing systems.

PCBs for high-power applications often feature thick copper traces , which act as pathways for heat dissipation. This technique increases the surface area for heat spreading, reducing hotspots.

Thermal vias are essential in multi-layer PCBs. These plated-through holes connect layers and transfer heat vertically to distribute it evenly across the board. When combined with heat sinks, thermal vias maximize thermal efficiency.

Materials like aluminum PCBs, ceramic PCBs, and copper cores are excellent for managing heat in high-power or high-temperature environments.

Ceramic PCBs : Known for their superior thermal conductivity and stability in harsh environments.

Aluminum PCBs : Feature a dielectric layer for efficient heat transfer to an aluminum base.

Heat pipes use a fluid cycle to transfer heat efficiently in space-constrained devices. They are often combined with heat sinks to manage heat in high-density PCBs.

Strategic placement of components and careful layout design can significantly enhance heat dissipation. For example:

Place high-power components near heat sinks or vents.

Avoid stacking heat-sensitive parts over heating elements.

Stagger components to improve airflow.

Heat sinks play a pivotal role in thermal management, especially in applications where natural dissipation is insufficient. Here's why heat sinks are indispensable:

Scalability : Heat sinks can be customized for a wide range of applications, from low-power devices to industrial-grade systems.

Efficiency : By increasing the surface area for heat dissipation, heat sinks prevent overheating even in compact designs.

Cost-Effectiveness : Heat sinks offer a long-term, maintenance-free solution for managing heat.

While heat sinks are highly effective, their performance can be amplified by combining them with other techniques:

Thermal Pads and Grease : Enhance thermal contact between the heat sink and the PCB.

Copper Coins : Localized heat dissipation under high-power components.

Heat Spreading Layers : Distribute heat laterally before transferring it to the heat sink.

To achieve optimal thermal performance, follow these design best practices:

Component Placement : Position heat sources strategically to optimize airflow and cooling.

Layer Stacking : Use internal power layers to spread heat efficiently.

Thermal Analysis : Simulate heat flow during the design phase to identify potential hotspots.

With the rise of high-density electronics, thermal management technologies are evolving. Emerging innovations include:

Graphene-Based Heat Sinks : Offering unparalleled thermal conductivity.

Smart Cooling Systems : Combining IoT-enabled sensors for real-time temperature monitoring.

3D Printed Heat Sinks : Enabling complex, lightweight designs for unique PCB configurations.

Heat management is critical to the performance and longevity of modern PCBs. From integrating heat sinks and thermal vias to optimizing layouts and materials, a comprehensive approach is essential.

At Enner , we provide tailored heat dissipation solutions, including custom-designed heat sinks, to meet the most challenging thermal demands. Contact us today to learn more about our advanced PCB cooling technologies and how we can help optimize your designs for maximum performance and reliability. Visit our website or call us to speak with an expert about your thermal management needs.

By continuing to use the site you agree to our privacy policy Terms and Conditions.