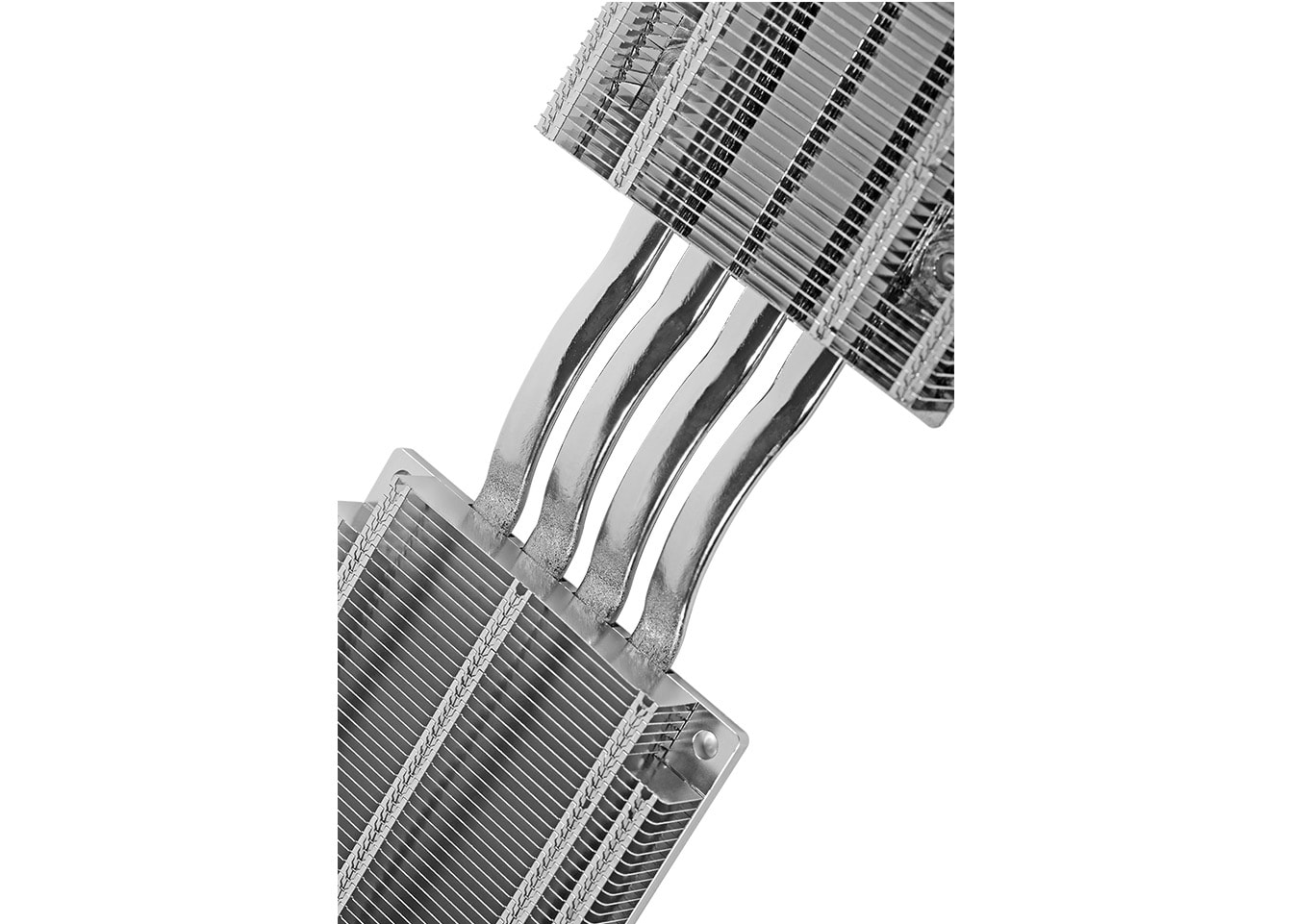

When it comes to cooling solutions for high-performance electronics, heat pipes play a crucial role in managing heat transfer. Unlike solid metals, heat pipes have unique thermal conductivity properties that make them ideal for efficient thermal management in modern devices. In this article, we'll dive into the factors influencing heat pipe thermal conductivity and how it compares to solid metals like copper and aluminum. We will also discuss how to leverage these properties to design optimal cooling solutions.

Thermal conductivity refers to the ability of a material to conduct heat. It's measured in watts per meter per degree Kelvin (W/m·K). For most solid metals, thermal conductivity remains constant. For example, copper has a thermal conductivity of around 390 W/m·K, which makes it an excellent conductor of heat. However, heat pipes are different. Their thermal conductivity can vary significantly, ranging from 1,500 W/m·K to 50,000 W/m·K for electronics cooling applications. This vast difference is one of the reasons heat pipes are so effective in high-performance heat sinks.

The thermal conductivity of a heat pipe is not a fixed value; it depends on several factors. One of the main contributors to this variability is the length of the heat pipe. The longer the heat pipe, the greater its effective thermal conductivity. In essence, the heat is transferred in stages through the heat pipe, which consists of a metal casing, a working fluid (usually water), and the process of evaporation and condensation.

When heat is applied to the heat pipe, the liquid inside evaporates, turning into vapor. The vapor then moves through the pipe and condenses at the other end. This phase change dramatically reduces the thermal resistance, thus increasing the overall thermal conductivity. As the heat travels through the heat pipe, the efficiency of heat transfer improves, especially over longer distances.

The length and diameter of a heat pipe play a significant role in its thermal conductivity. As we mentioned earlier, the effective thermal conductivity increases with length. However, there is an important distinction between the actual length of the heat pipe and its "effective length," which is calculated by considering the evaporator, condenser, and adiabatic sections of the pipe.

On the other hand, the diameter of the heat pipe has an inverse relationship with its thermal conductivity. Smaller diameter heat pipes tend to have higher effective thermal conductivity compared to larger ones. This is due to the ratio of the cross-sectional area, which decreases in smaller pipes, leading to more efficient heat transfer.

Heat pipes are essential for designing efficient heat sinks, especially in applications where space is limited and high thermal loads need to be managed. Engineers must consider several factors when selecting the right heat pipe for a specific application. First, the power being transported (Q), the effective length of the heat pipe, and the temperature difference between the evaporator and condenser (ΔT) all contribute to the overall thermal conductivity.

For instance, when designing a heat sink for a high-performance CPU or GPU, heat pipes can significantly reduce the size of the required heat sink while maintaining excellent cooling efficiency. In such cases, choosing the correct diameter and length of the heat pipe based on the thermal load and available space can optimize heat dissipation, leading to better device performance and longevity.

While solid metals like copper and aluminum provide reliable heat dissipation, they are limited by their constant thermal conductivity. In contrast, heat pipes benefit from multiple stages of heat transfer that greatly enhance their ability to conduct heat over long distances. This makes heat pipes an indispensable component in cooling systems that need to manage substantial heat loads in compact designs.

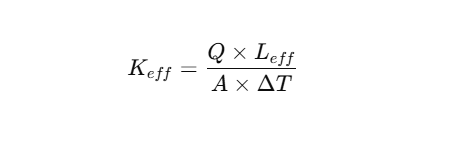

To accurately calculate the thermal conductivity of a heat pipe, you can use the following formula:

Where:

This formula helps engineers understand how efficient the heat pipe will be in transporting heat, which is essential for optimizing heat sink designs.

In high-performance electronics, such as gaming systems, servers, and other advanced devices, heat management is critical. Heat pipes are often integrated into heat sinks to provide superior thermal conductivity and enhance cooling performance. However, it's important to ensure that all components are chosen based on their specific thermal characteristics to prevent overheating and maintain optimal device performance.

For example, using a longer heat pipe can improve the heat transfer efficiency, but it may also require more space. Therefore, balancing the heat pipe's length and diameter with the available space and the power being dissipated is crucial in high-performance applications.

Heat pipes offer a significant advantage over solid metals like copper in thermal management systems. Their ability to provide high thermal conductivity, especially in compact and high-power applications, makes them an invaluable tool for engineers. By understanding the factors that influence heat pipe thermal conductivity—such as length, diameter, and temperature differences—designers can optimize their cooling systems for maximum efficiency.

If you're looking to improve the cooling performance of your electronic devices, consider leveraging heat pipes in your design. For more expert insights and innovative solutions for your heat management needs, reach out to Enner today. Our team of professionals is here to help you design efficient, high-performance cooling systems for your projects.

By continuing to use the site you agree to our privacy policy Terms and Conditions.