News

Site Editor

Site

/uploads/image/658e1b5398ef3.png

In the realm of thermal management, heat pipes and vapor chambers have emerged as critical technologies, particularly in the cooling of modern electronic components.

Site

/uploads/image/658e1b5398ef3.png

In the realm of thermal management, heat pipes and vapor chambers have emerged as critical technologies, particularly in the cooling of modern electronic components.

Understanding Heat Pipes and Vapor Chambers: The Future of Thermal Management

Views: 1316

Author: Site Editor

Publish Time: 2024-11-01

Origin: Site

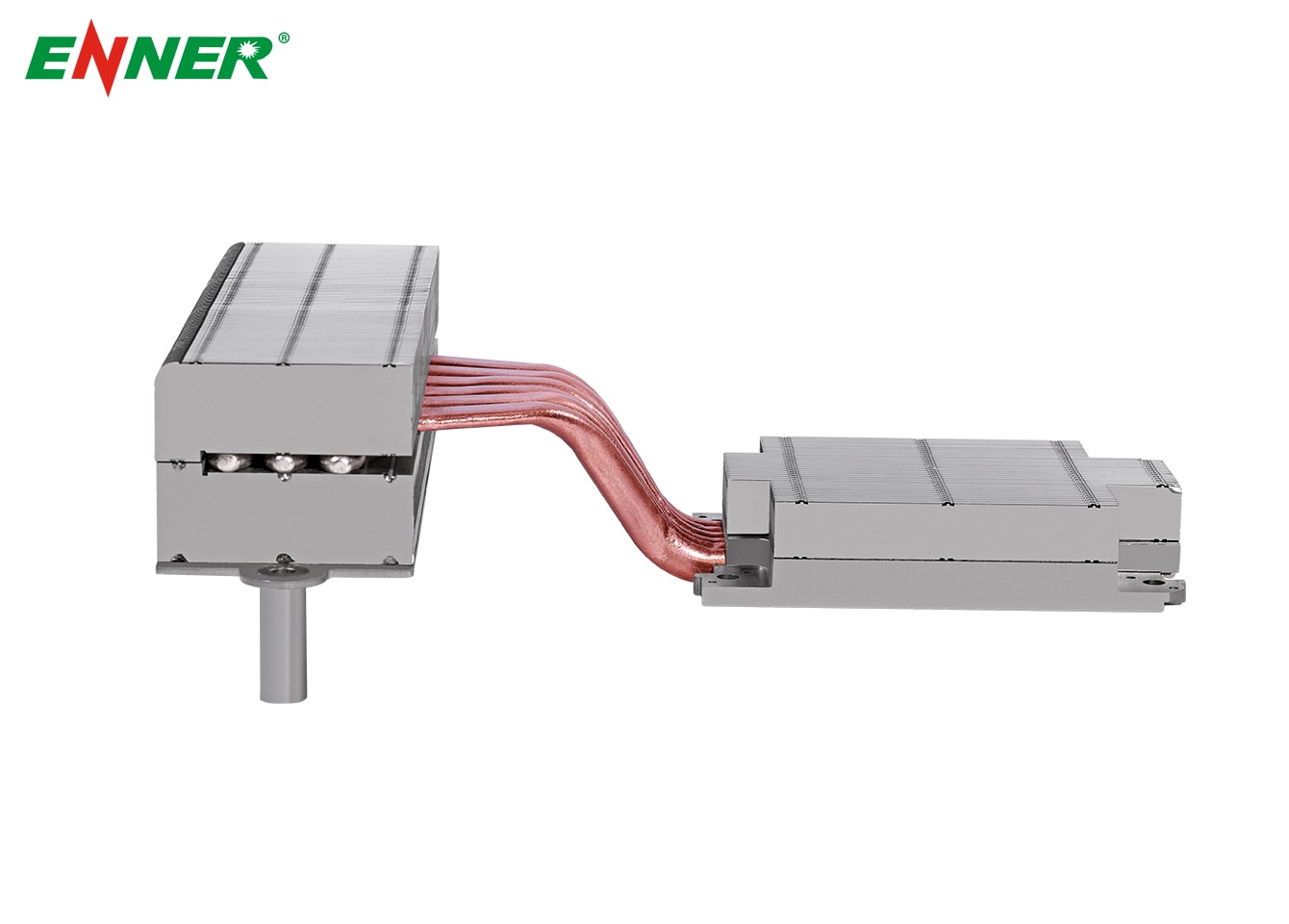

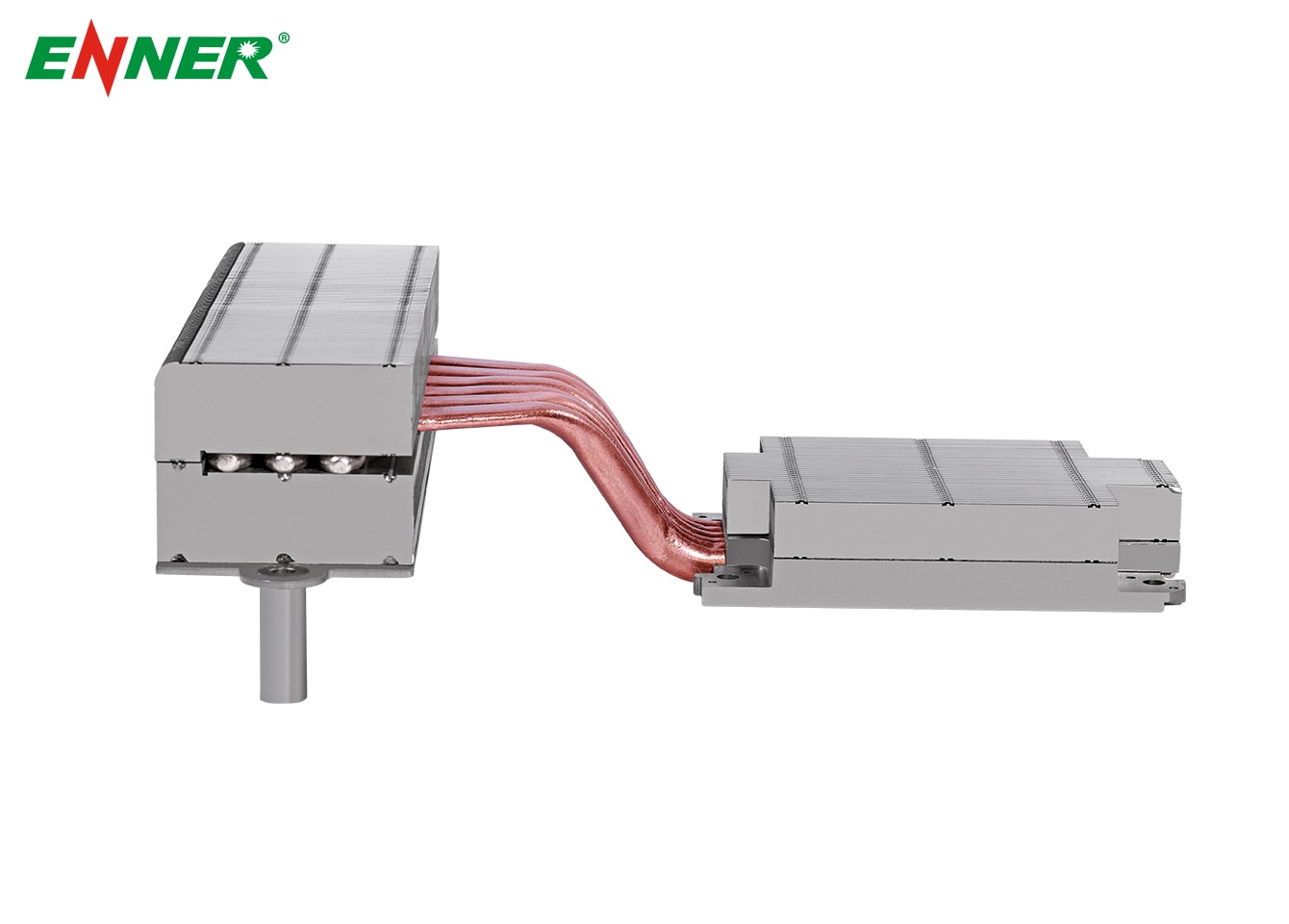

In the realm of thermal management, heat pipes and vapor chambers have emerged as critical technologies, particularly in the cooling of modern electronic components. As electronics become more compact and powerful, the demand for efficient heat dissipation systems grows. This article will explore how heat pipes and vapor chambers work, their applications, and the advantages they offer over traditional cooling methods.

How Do Heat Pipes Work?

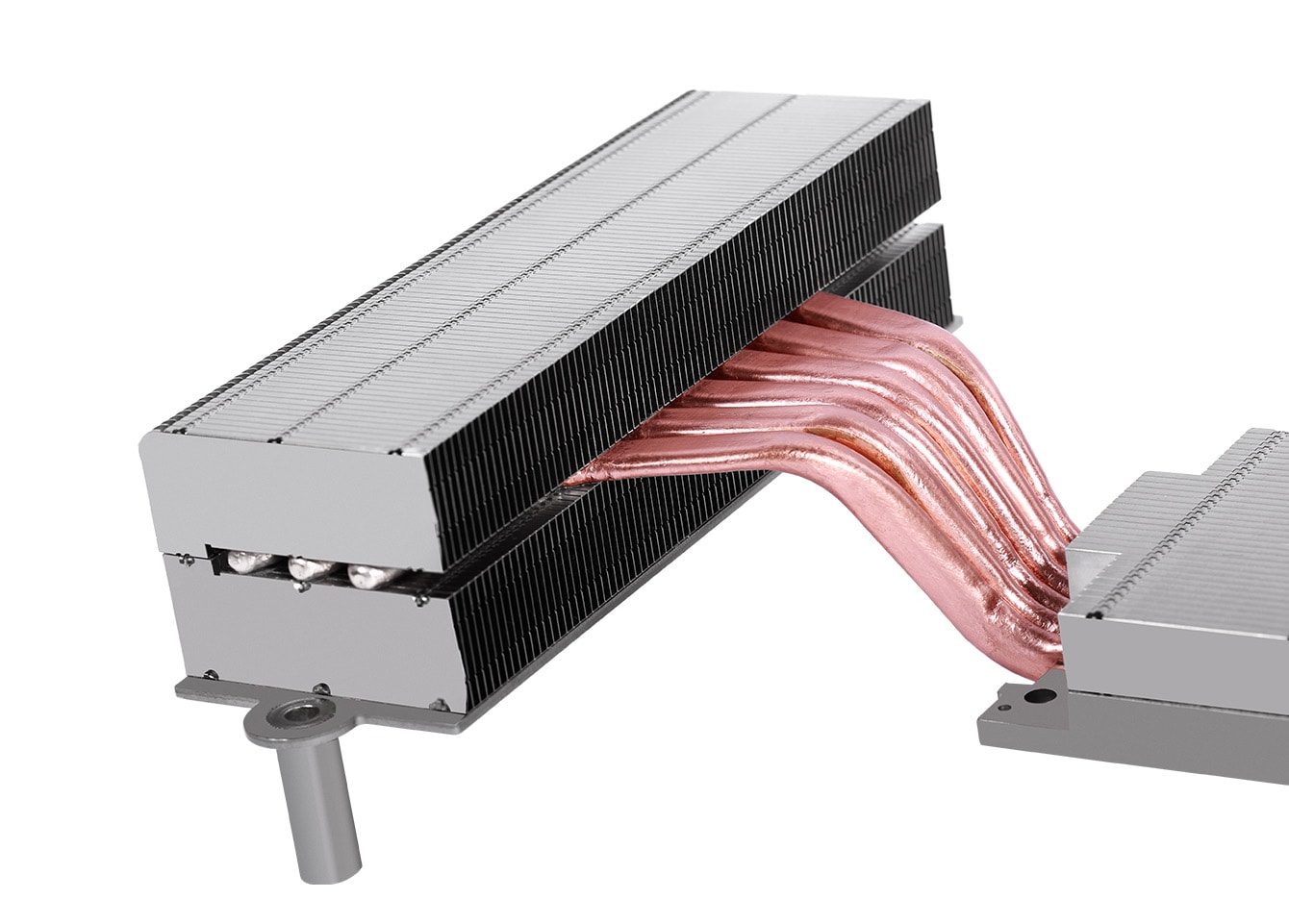

Heat pipes are passive thermal devices that transfer heat efficiently. Comprised of three essential components—a vacuum-sealed enclosure, a wicking structure, and a working fluid—they leverage the principles of phase change to move heat from one area to another.

The Basic Principles

-

Evaporation : When heat is applied to the heat pipe, the working fluid within it (commonly de-ionized water) absorbs this heat and evaporates into a vapor.

-

Transportation : The vapor moves toward a cooler area of the heat pipe, usually located near cooling fins or a heatsink.

-

Condensation : As the vapor reaches the cooler section, it releases heat and condenses back into a liquid.

-

Return : The liquid is drawn back to the heat source through capillary action, facilitated by the wicking structure lining the interior of the pipe. This cycle continues as long as heat is applied.

Configurations and Size Variations

Heat pipes can come in various sizes, typically ranging from 2mm to 12mm in diameter. They can also be flattened or bent, allowing them to fit into tight spaces in modern electronic designs. The thickness and porosity of the wick structure can be tailored to optimize thermal performance, adjusting the maximum power carrying capacity (Qmax).

For example, larger diameter heat pipes can transport more heat, and Qmax is additive—two pipes can handle double the power of one. However, bending a heat pipe or operating it at high altitudes can decrease its efficiency.

Vapor Chambers: The Next Step

Vapor chambers operate on the same principles as heat pipes but are designed for more extensive applications. They can spread heat across a larger surface area, making them ideal for dissipating heat from high-performance CPUs and GPUs. A significant difference lies in their aspect ratio—vapor chambers can be much flatter, with width-to-height ratios of up to 60:1.

Typical Configurations

-

Slice Chambers : These feature flattened copper pipes with internal structures for improved wicking.

-

Standard Vapor Chambers : Comprised of two copper plates enclosing a wicking structure, they provide a robust heat spread across their surfaces.

-

Ultra-thin Chambers : Created from etched copper sheets, they are lightweight and efficient for compact designs.

Importance of Heat Pipe and Vapor Chamber Technologies

Modern electronic components produce increasingly high thermal design power and power density. Traditional cooling methods, such as solid metal heat sinks, often fall short in efficiently managing this heat. Heat pipes and vapor chambers dramatically increase thermal conductivity—up to 6,000 W/(mK)—compared to solid copper (400 W/(mK)) or aluminum (200 W/(mK)). This exceptional thermal performance is essential for managing the heat output of densely packed microchips.

Key Advantages

-

High Thermal Conductivity : Heat pipes can conduct heat much more efficiently than solid materials, enabling effective cooling in tight spaces.

-

Flexibility : They can be designed in various shapes and sizes, making them suitable for applications where space is limited.

-

Improved Heat Sink Efficiency : By transporting heat to underutilized areas of a heat sink, heat pipes enhance overall cooling performance.

-

Longevity : With no moving parts and minimal degradation, heat pipes can have an operational life of 20 years or more.

When to Use Heat Pipes or Vapor Chambers

Heat pipes and vapor chambers are particularly beneficial in scenarios where:

-

Heat needs to be transported over distances greater than 50mm.

-

The base area of a heat sink is significantly larger than the heat source.

-

There are strict weight limitations that solid copper heat sinks cannot meet.

-

Thermal requirements are below 40°C with low airflow conditions.

Examples of Applications

Heat pipes and vapor chambers are widely used in various industries, from consumer electronics and computer hardware to aerospace and automotive systems. They are essential for managing thermal output in devices like laptops, gaming consoles, and even satellites.

Conclusion

Heat pipes and vapor chambers represent the cutting-edge of thermal management technology. Their ability to efficiently transfer heat through phase change processes enables modern electronic devices to perform optimally while maintaining thermal stability. As electronic components continue to evolve, the role of these innovative cooling solutions will only become more critical.

For businesses looking to enhance their thermal management systems, partnering with experienced manufacturers like ENNER can lead to tailored solutions that meet specific cooling requirements. Explore our advanced thermal management products today and see how we can help you achieve optimal performance in your electronic designs!

Contact ENNER for Custom Thermal Solutions