Heat management is critical in a world where electronic devices and industrial systems are becoming more powerful and compact. Heat pipe technology plays an essential role in efficiently transferring heat from high-temperature areas to cooler regions. This article explores how heat pipes work, their applications, and why they are increasingly popular in various industries.

A heat pipe is a passive device designed to transfer heat efficiently from one location to another. Unlike traditional cooling methods, heat pipes use the evaporation and condensation of a working fluid to move heat. The process is highly effective and requires no mechanical components, making heat pipes reliable and maintenance-free.

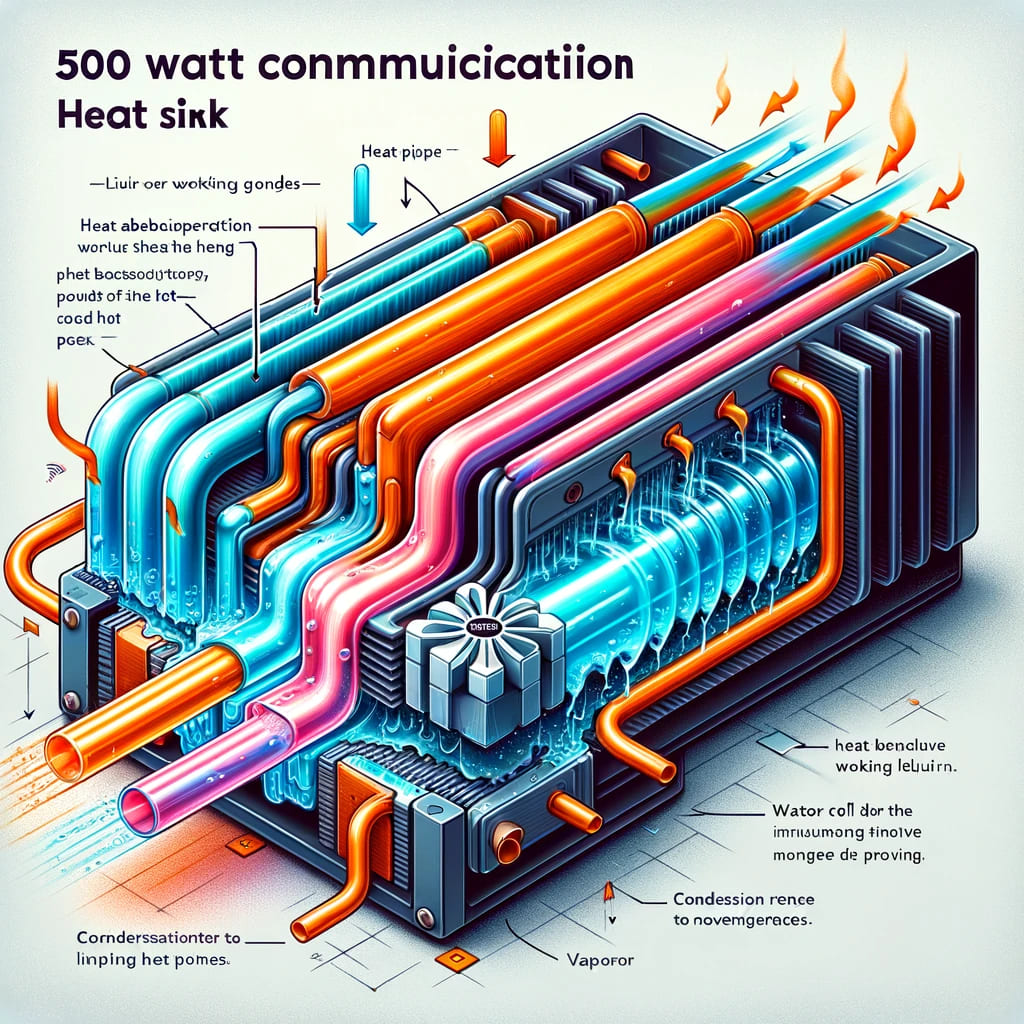

At the core of a heat pipe is a sealed vessel containing a liquid. When one end of the pipe gets heated, the liquid inside evaporates. The vapor then travels to the cooler end of the pipe, where it condenses and releases heat. The condensed liquid is then returned to the hot end through capillary action, repeating the cycle. This process allows heat pipes to transfer heat much faster than conventional methods.

The operation of a heat pipe is based on two main principles: phase change and capillary action. When heat is applied to the pipe, it causes the liquid inside to evaporate. The vapor moves through the pipe towards the cooler end, where it condenses back into a liquid, releasing the heat.

Capillary action plays a crucial role in returning the liquid to the hot end. This is achieved through the wick structure inside the pipe, which draws the condensed liquid back to the heat source. The cycle continues as long as there is a temperature difference between the two ends of the pipe.

The simplicity and efficiency of this process make heat pipes an excellent solution for thermal management in various applications.

While the core principle of heat pipes remains the same, different types have been developed to meet specific needs. Some of the most common types include:

Standard Heat Pipes: These are the most basic form of heat pipes and are used in many general applications, such as cooling electronic devices.

Vapor Chamber Heat Pipes: Used in situations where uniform heat distribution is needed, vapor chambers spread heat evenly across a surface. They are commonly used in high-performance electronics and LED lighting systems.

Loop Heat Pipes: Designed for use in confined spaces, loop heat pipes are popular in aerospace applications. Their unique design allows them to operate efficiently in environments with limited space and varying gravitational conditions.

Thermosyphons: These heat pipes use gravity to help move the working fluid and can be much longer than traditional heat pipes. They are often used in industrial and outdoor applications.

Heat pipes are used in a wide range of industries due to their efficiency and versatility. Some of the most prominent applications include:

Electronics Cooling: Heat pipes are essential in cooling high-performance devices such as CPUs, GPUs, and gaming laptops. They prevent overheating, ensuring that electronic components function optimally and have a longer lifespan.

Aerospace: In spacecraft and satellites, heat pipes manage the temperature of critical components in the extreme conditions of space. They help maintain stable operating temperatures, ensuring the reliability of these high-tech systems.

Automotive: In electric vehicles, heat pipes are used for battery thermal management, ensuring that batteries remain within safe temperature ranges for optimal performance and longevity.

Renewable Energy: Heat pipes play a role in solar thermal systems by efficiently transferring heat from solar collectors to storage tanks or heat exchangers.

HVAC Systems: Heat pipes are also used in heating, ventilation, and air conditioning systems, particularly for energy recovery and efficient temperature control.

Heat pipes offer several advantages over traditional cooling methods:

Efficiency: Heat pipes have a very high thermal conductivity, allowing them to transfer heat quickly and effectively.

Compactness: Their passive design means they can be used in compact spaces without the need for bulky components like fans or compressors.

Reliability: Since heat pipes have no moving parts, they are highly reliable and require minimal maintenance.

Versatility: With various designs available, heat pipes can be customized for use in a wide range of industries and applications.

Heat pipes are an innovative and efficient solution for thermal management. From cooling electronics to maintaining optimal temperatures in aerospace applications, they are indispensable in many fields. As industries continue to advance, heat pipe technology will remain a key player in ensuring the performance and longevity of modern devices.

If you're looking for reliable and efficient thermal management solutions, Enner offers a range of advanced heat pipe systems tailored to meet your needs. Contact us today to learn more about how heat pipe technology can benefit your applications.

By continuing to use the site you agree to our privacy policy Terms and Conditions.