Electronic devices generate heat as a natural by-product of their operation. This heat primarily comes from the dissipation of electrical energy as it passes through semiconductors or passive components. Left unchecked, overheating can significantly degrade device performance, reduce reliability, and even cause permanent damage. Effective thermal management is critical for maintaining optimal operating temperatures, ensuring the longevity and efficiency of electronic devices.

When the junction temperature of electronic components, such as programmable array logic (PAL) chips, dynamic random-access memory (DRAM), or microprocessors, exceeds the manufacturer-specified maximum, their failure rate increases exponentially. Overheating not only affects component durability but also contributes to issues like signal noise due to excessive movement of free electrons within semiconductors. Thus, the core objective of thermal management is to keep the junction temperature below critical levels.

Nature facilitates heat transfer through three fundamental mechanisms:conduction,convection, andradiation. Each plays a vital role in electronic thermal design.

Convection involves the transfer of heat through the movement and mixing of fluid elements, which can either be natural or forced.

Natural Convection:This occurs due to temperature-induced density variations within the cooling medium, leading to buoyancy-driven fluid motion.

Forced Convection:This relies on external forces like fans or pumps to move the cooling medium across heated surfaces.

Convection is governed by Newton's Law of Cooling:

Conduction transfers heat from regions of higher temperature to lower temperature within a material. In electronics, it occurs primarily through the lattice vibrations of atoms and the movement of free electrons. The Fourier’s Law of Heat Conduction describes this process:

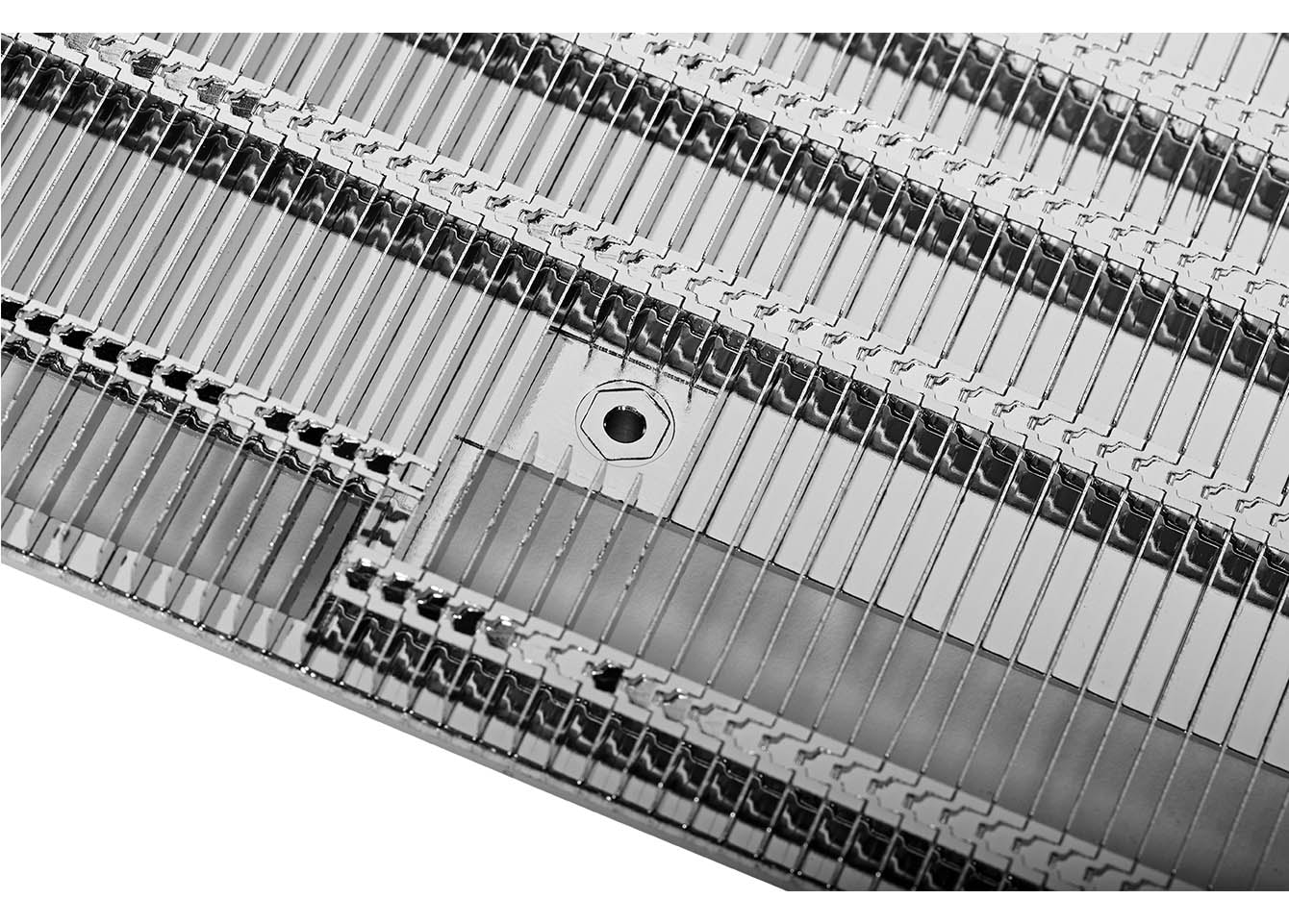

Materials like aluminum (k=236k=236W/m·K) and copper (k=400k=400W/m·K) are commonly used in heat sinks due to their high thermal conductivity. For enhanced performance, some heat sinks combine copper and aluminum to optimize thermal conduction and weight.

Materials like aluminum (k=236k=236W/m·K) and copper (k=400k=400W/m·K) are commonly used in heat sinks due to their high thermal conductivity. For enhanced performance, some heat sinks combine copper and aluminum to optimize thermal conduction and weight.

Additionally,thermal interface materials (TIMs)like thermal paste or conductive pads fill microscopic gaps between surfaces, reducing thermal resistance and improving heat transfer. While TIMs have high thermal conductivity, their effectiveness also depends on minimizingthermal resistanceat interfaces.

Radiation is the transfer of heat via electromagnetic waves and can occur even in a vacuum. Governed by the Stefan-Boltzmann Law:

While radiation becomes significant at extremely high temperatures or in space environments, its contribution to heat dissipation in most electronic devices is minimal. A common misconception is that black-colored heat sinks radiate heat more efficiently. However, color affects only visible light absorption, not infrared radiation, which dominates at typical device operating temperatures.

To design efficient thermal management systems:

Managing heat effectively is crucial for preserving the performance and reliability of electronic devices. Understanding the mechanisms of conduction, convection, and radiation allows engineers to develop innovative solutions for dissipating heat. As electronics continue to evolve, investing in robust thermal management strategies will ensure devices operate safely and efficiently, even under demanding conditions.

At ENNER , we offer a wide range of thermal management solutions, including heatpipe cooling systems , vapor chamber heatsinks , CNC machining parts and accessories, ensuring your equipment performs at its best even under high heat conditions.

By continuing to use the site you agree to our privacy policy Terms and Conditions.