LED technology has completely transformed the lighting industry. Its energy-saving, high-efficiency, and environmentally friendly characteristics have made it widely popular in household, commercial, and industrial fields. However, the performance and lifespan of LED lights are not solely determined by the technology of the LED itself. Among them, heat dissipation management is a crucial factor. This article will explore how heat sinks affect the lifespan of LED lights and provide some practical strategies for optimizing heat dissipation performance.

The operating efficiency of LED lights is significantly affected by the working temperature. Even high-quality LED lights will experience a significant performance reduction if the heat dissipation is poor, and may even cause the following problems:

When the temperature exceeds the tolerance limit of the LED materials, the lamp beads may suffer irreversible physical damage, leading to device failure. This situation is usually accompanied by the cracking of the LED chip or packaging.

High temperatures will accelerate the aging of the internal materials of LEDs, resulting in a decline in luminous efficiency. The lifespan of LEDs is generally defined by the reduction of their light output to 70% of the initial value (referred to as the L70 point), and an increase in temperature will significantly shorten the time to reach the L70 point. For example, in an environment of 75°C, the lifespan of LEDs may be only 39,000 hours, while at 50°C, it can be extended to 90,000 hours.

Even without long-term damage, high temperatures will immediately affect the light output of LEDs. The performance of inferior LEDs may decline by as much as 70% in an environment of 75°C.

High temperatures may also change the color temperature of white LEDs, causing the light color to change from white to blue or other unnatural hues. This change is often irreversible.

Heat dissipation management for LED technology is of vital importance and can be achieved through the following methods:

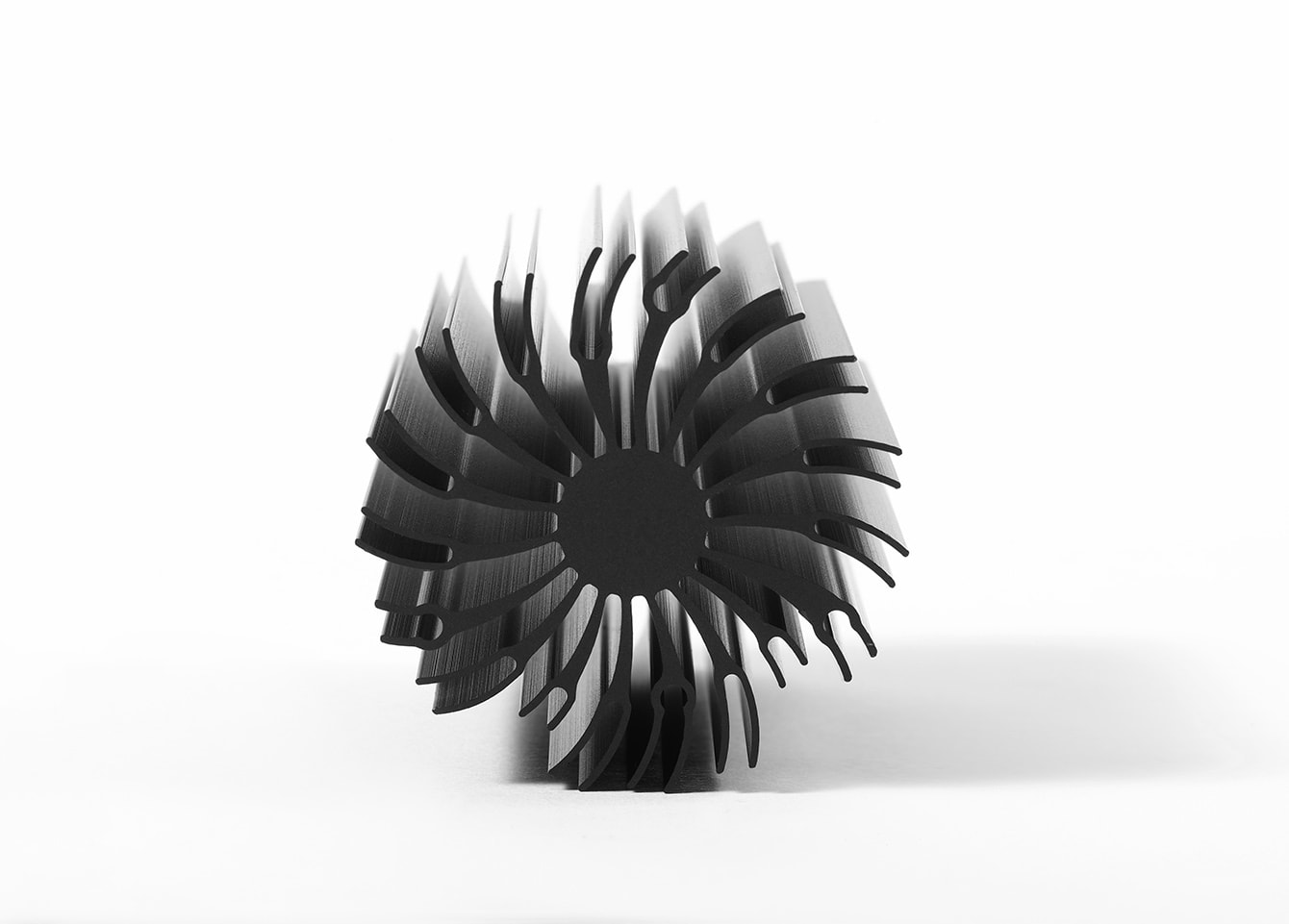

Aluminum is commonly used to make heat sinks due to its good thermal conductivity. For high-power LED lights, thermal conductive adhesive pads or copper sheets can be added on the basis of aluminum materials to enhance thermal conductivity.

The surface area, shape, and thickness of the heat sink will directly affect the heat dissipation efficiency. For example:

A 1W LED light requires a heat sink surface area of 50 - 60 square centimeters.

A 3W LED light is recommended to use a heat sink surface area of 150 square centimeters.

Applying thermal conductive silicone grease or using thermal conductive adhesive pads between the LED and the heat sink can fill tiny gaps and improve the thermal conduction efficiency.

For high-power LED luminaires, relying solely on heat sinks may not be sufficient to solve the high-temperature problem. At this time, active heat dissipation technologies such as fans or liquid cooling can be introduced to further improve the heat dissipation performance.

A domestic city conducted a three-month test on LED street lights and found that the light decay of the luminaires reached 20.4% due to excessively high working temperatures. The main reason was the inadequate design of the heat sink, which failed to effectively reduce the working temperature of the LEDs. This shows that ensuring good heat dissipation performance is of crucial importance in practical applications.

LED lights only convert 20% - 30% of electrical energy into light energy, and the remaining 70% - 80% is converted into heat energy. If this heat cannot be effectively dissipated, it will seriously affect the performance and lifespan of the luminaires. By selecting high-quality LED products, designing a reasonable heat dissipation system, and using appropriate heat dissipation materials, the service life of LED lights can be significantly extended.

Whether it is for household lighting or commercial use, correct heat dissipation management is the key to achieving high efficiency and a long lifespan for LED lights. If you need to select high-performance heat sinks for LED luminaires or customize heat dissipation solutions, please feel free to contact us. Our professional team will provide you with the best solutions.

At ENNER , we offer a wide range of thermal management solutions, including heatpipe cooling systems , vapor chamber heatsinks , CNC machining parts and accessories, ensuring your equipment performs at its best even under high heat conditions.

By continuing to use the site you agree to our privacy policy Terms and Conditions.